![]()

![]()

Geometric Construction and Solver Settings

Introduction and Model Dimensions

In this tutorial, a circuit breaker consisting of two contact springs connected by a bridge is analyzed. The contact springs will be constructed using the line and arc curve tools. The resulting curve can then be traced to form a solid. On either side of the contact area a gold pad is associated that can be constructed with the extrusion tool. For the construction of the bridge, a local coordinate system is employed to make creation of the brick easier.

One matter of concern is the current flow from one contact over the bridge to the other contact. Therefore, two current ports are defined for the stationary current solver. If the current amplitude increases too much (e.g. caused by a short circuit) the bridge is pulled away from the springs - which is an effect caused by the current's magnetic field. The current field can be calculated by the stationary current solver and will be used as a source field for a magnetostatic calculation.

We strongly recommend that you carefully read through the CST EM STUDIO Workflow & Solver Overview manual before starting this tutorial.

All dimensions in the detail drawing are given in cm.

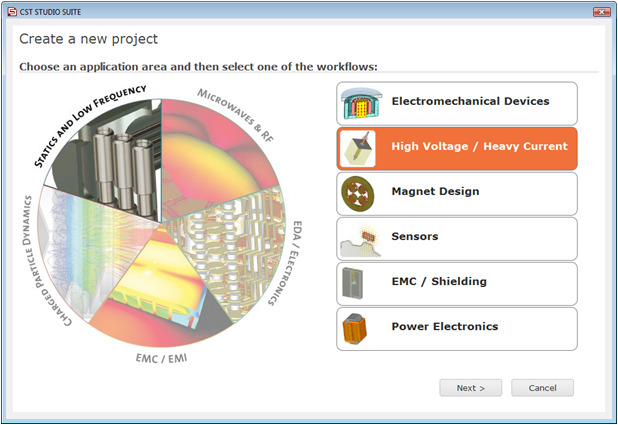

After launching the CST STUDIO SUITE you will enter the

start screen showing you a list of recently opened projects and allowing

you to specify the application which suits your requirements best. The

easiest way to get started is to configure a project template which sets

the basic settings that are meaningful for your typical application. Therefore

click on the Create Project ![]() button in the New Project

section.

button in the New Project

section.

Next you should chose the application area, which is Statics and Low Frequency for the example in this tutorial and then select the workflow by double-clicking on the corresponding entry.

For the circuit breaker, please select High

Voltage / Heavy Current ![]() Interrupters

Interrupters

![]() Stationary

Current

Stationary

Current ![]() .

.

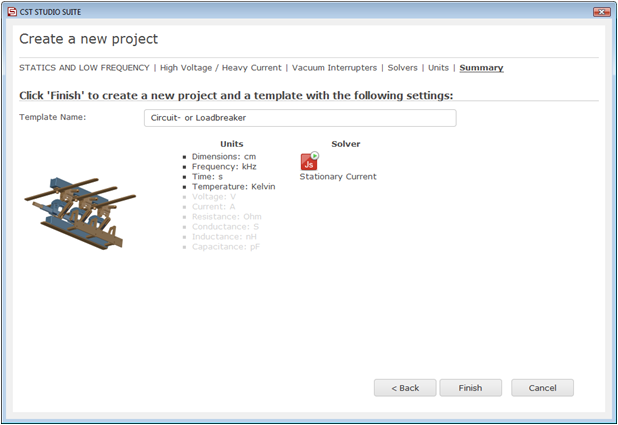

At last you are requested to select the units which fit your application best. The circuit breaker device in this tutorial has dimensions given in cm. Therefore select cm from the Dimensions drop-down list. For the specific application in this tutorial the other settings can be left unchanged. After clicking the Next button, you can give the project template a name and review a summary of your initial settings.

Finally, click the Finish button to save the project template and to create a new project with appropriate settings. CST EM STUDIO will be launched automatically due to the choice of the application area Statics and Low Frequency.

Please note: When you click again on File: New and Recent you will see that the recently defined template appears below the Project Templates section. For further projects in the same application area you can simply click on this template entry to launch CST EM STUDIO with useful basic settings. It is not necessary to define a new template each time. You are now able to start the software with reasonable initial settings quickly with just one click on the corresponding template.

Please note:

All settings made for a project template can be modified later on during

the construction of your model. For example, the units can be modified

in the units dialog box (Home:

Settings ![]() Units

Units ![]() )

and the solver type can be selected in the Home:

Simulation

)

and the solver type can be selected in the Home:

Simulation ![]() Start Simulation

drop-down list.

Start Simulation

drop-down list.

Once you have entered the modeling view, the background

properties should be adjusted. Because the structure will be defined in

a vacuum background, you must define the size of the surrounding empty

space. Therefore, select Modeling:

Materials ![]() Background

Background ![]() to open the Background Properties

dialog box. The Material type

has been set to Normal already

by the project template. Please deactivate the Apply

in all directions checkbox, enter 2 cm for the Lower

Y, Upper Y, Lower

Z and Upper Z distance.

No space is added for X-distances because the circuit breaker needs to

touch the boundaries in order to apply the current port sources correctly

in a later step, where the current distribution is used as source for

a magnetostatic simulation. Therefore enter 0 cm in the Lower

X and Upper X distance

fields and confirm by pressing the OK

button.

to open the Background Properties

dialog box. The Material type

has been set to Normal already

by the project template. Please deactivate the Apply

in all directions checkbox, enter 2 cm for the Lower

Y, Upper Y, Lower

Z and Upper Z distance.

No space is added for X-distances because the circuit breaker needs to

touch the boundaries in order to apply the current port sources correctly

in a later step, where the current distribution is used as source for

a magnetostatic simulation. Therefore enter 0 cm in the Lower

X and Upper X distance

fields and confirm by pressing the OK

button.

The first step for the circuit breaker is the construction

of the right contact which uses the trace function of a curve. Therefore,

define the a line (Modeling:

Curves ![]() Curves

Curves

![]() Line

Line ![]() )

with

)

with

first point at X = 5, Y = 2 and

second point at X = 2, Y = 2.

You can do this by clicking at the corresponding coordinates in the main view or by pressing the Tab or Esc key and enter the coordinates numerically.

The next part of the curve is an arc. Select Modeling:

Curves ![]() Curves

Curves ![]() Arc

Arc ![]() and define

and define

the arc center at X = 2, Y = 1;

start point at X1 = 2, Y1 = 0;

end point at X2 = 2, Y2 = 2.

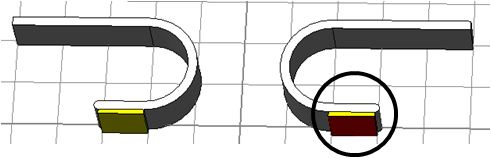

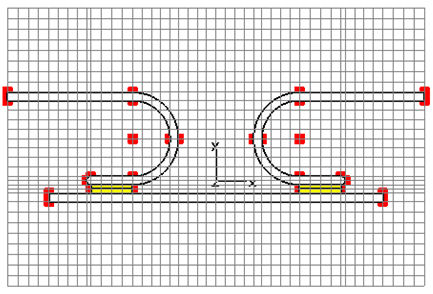

Check your settings against the screenshots below and verify that the arc is oriented correctly (otherwise you can change the arc's orientation in the dialog box). Finally, confirm with OK.

|

|

|

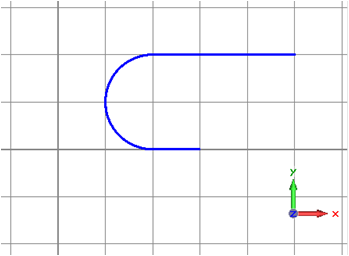

The last curve element is another line and can be created

similar to the first one. Activate the curve line tool (Modeling:

Curves ![]() Curves

Curves ![]() Line

Line ![]() )

and enter the points X = 2, Y = 0

and X = 3, Y = 0. The screenshot

below shows the current model status:

)

and enter the points X = 2, Y = 0

and X = 3, Y = 0. The screenshot

below shows the current model status:

Finally, the curve has to be transformed into a solid

to model the contact. The right tool for this procedure is the Trace

from Curve tool. Select Modeling:

Curves ![]() Curve Tools

Curve Tools ![]() Trace from Curve

Trace from Curve ![]() and double-click on any curve element when asked for the curve. Before

you confirm the trace creation, a new material must be defined. Select

[New Material...] from the Material drop down list in the trace

definition dialog box and define the material copper. This requires changing

the Material Name to copper,

selecting a new color and inputting an electric conductivity of 5.8e7 S/m in the Conductivity

tab.

and double-click on any curve element when asked for the curve. Before

you confirm the trace creation, a new material must be defined. Select

[New Material...] from the Material drop down list in the trace

definition dialog box and define the material copper. This requires changing

the Material Name to copper,

selecting a new color and inputting an electric conductivity of 5.8e7 S/m in the Conductivity

tab.

|

|

|

Please note: The defined material copper will be available inside the current project for the further creation of other solids. However, if you want to save this specific material definition for use in other projects, you may check the button Add to material library. You will have access to this material database by clicking on Load from Material Library in the Materials context menu in the navigation tree.

Pressing the OK button stores the material and closes the dialog box so that you can continue to enter the trace parameters. Back in the trace creation dialog box, please check that the Material has changed to copper. Enter contact spring in the Name field. Furthermore,

define Thickness = 1, Width = 0.2

and Rounded Caps at the End.

Please note that the end of the curve depends on which part of the curve you chose for the trace action. This fact must be considered in the construction, so you should ensure that the preview of the shape has a rounded cap at the shorter end. If not, it is only necessary to switch off the Rounded caps at the End and enable them at the Start of the curve.

|

|

|

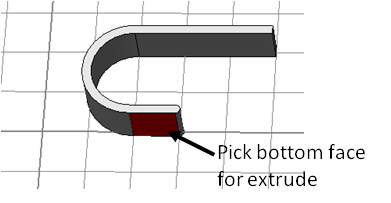

To complete the construction of the right contact, the definition of a contact pad is still required. This task is easily done by extruding the bottom face of the spring.

To perform the extrusion, the desired face must be chosen

beforehand. Therefore, activate the pick face tool with the shortcut

f or via Modeling:

Picks ![]() Picks (

Picks (![]() )

double-click on the bottom face of the spring. Then select Modeling:

Shapes

)

double-click on the bottom face of the spring. Then select Modeling:

Shapes ![]() Extrude

Extrude ![]() that opens a dialog box for the extrusion parameters. First, a new material

has to be defined because the contact pad is composed of gold. Choose

[New Material...] from the Material drop down list. In the New Material Parameters dialog box

that opens a dialog box for the extrusion parameters. First, a new material

has to be defined because the contact pad is composed of gold. Choose

[New Material...] from the Material drop down list. In the New Material Parameters dialog box

change the Material name to gold,

set the Type to Normal,

select a new color,

input an Electric conductivity of 4.5e7 S/m in the Conductivity Tab,

and store the material by pressing the OK button.

|

|

|

Back in the Extrude Face dialog box, enter a name for the solid (contact pad) and 0.1 for the Height; the other parameters can be left at their default values. Verify your settings by pressing the Preview button and finally close the dialog box by pressing the OK button.

|

|

|

Due to the symmetry of the structure, the left contact

can be produced by just one mirror operation. Therefore, select component1 (which contains the contact

pad as well as the contact spring) in the navigation tree and choose Transform from the context menu or

from the ribbon Modeling:

Tools ![]() Transform

Transform ![]() .

In order to mirror the structure correctly, select Mirror

as Operation, X

= 1 as the Mirror plane normal

and activate the Copy option:

.

In order to mirror the structure correctly, select Mirror

as Operation, X

= 1 as the Mirror plane normal

and activate the Copy option:

|

|

|

After confirming with OK, two new shapes will appear in the navigation tree named as the transformation originals with _1 added.

After modeling the contact, the pads of the bridge must be constructed. Therefore, pick the previously defined pad (contact pad) of the contact at the bottom and extrude it again.

First, select Modeling:

Picks ![]() Picks

Picks ![]() (shortcut: f) and double-click

on the bottom face. Then activate the extrude tool (Modeling:

Shapes

(shortcut: f) and double-click

on the bottom face. Then activate the extrude tool (Modeling:

Shapes ![]() Extrude

Extrude ![]() )

and enter

)

and enter

a Name (bridge pad),

a value of 0.1 for the Height and

choose [New Component...] from the Component drop down list.

In view of the fact that the bridge is physically independent, it is preferable to construct it as a new component; this makes it subsequently easier to manipulate, e.g. for transformations.

|

|

|

Again, check your settings and confirm with OK.

As previously carried out for the contact, the bridge's pad on the left side can be created with a mirror operation. This requires the newly created pad to be selected by double-clicking on it. Then select Transform from the context menu to start the transformation and repeat the previously made steps:

Select Mirror as Operation,

set the Mirror plane normal to X=1 and

activate the Copy option.

The last modeling step is the construction of the bridge. Up to this point, the construction has been performed in the global coordinate system because no relative construction was needed. For proper positioning, it is advisable to define the bridge using a working coordinate system (WCS) that introduces a local coordinate system. For this tutorial the WCS will be aligned in the middle of the bridge pads.

The working coordinate system can be switched on or off

by selecting Modeling:

WCS ![]() Local WCS

Local WCS ![]() .

It can be aligned with a point (or any other object) with Align

WCS (shortcut: w) which

can be found under Modeling:

WCS

.

It can be aligned with a point (or any other object) with Align

WCS (shortcut: w) which

can be found under Modeling:

WCS ![]() Align WCS

Align WCS ![]() as well. For the bridge construction,

as well. For the bridge construction,

activate the WCS (![]() ),

),

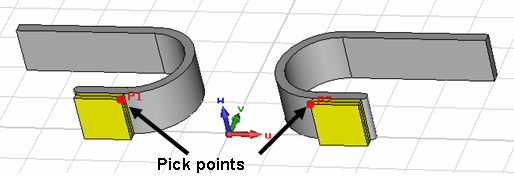

pick the two illustrated points

(Modeling:

Picks ![]() Picks

Picks ![]() ,

shortcut: p),

,

shortcut: p),

generate a new point with Modeling:

Picks ![]() Pick Point

Pick Point ![]() Mean Last Two Points

Mean Last Two Points

and align the WCS to this point

(Modeling:

WCS ![]() Align WCS

Align WCS ![]() ).

).

With the WCS in the right location it is now quite easy

to define the bridge. Therefore,select Modeling:

Shapes ![]() Brick

Brick

![]() to activate the Brick tool and

use the Tab key or double-click in the working plane to enter

to activate the Brick tool and

use the Tab key or double-click in the working plane to enter

the first point at U = 4, V = 0,

the second point at U = -4, V = -0.2,

and -1 for the height.

In the Brick dialog box you only have to enter a proper Name, e.g. bridge, and choose copper from the Material drop-down list.

|

|

|

Now, the geometric modeling is complete and now the solver settings have to be established.

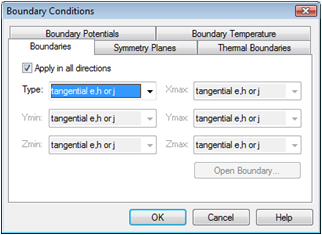

The calculation domain is bounded by six faces. A boundary

condition must be assigned to each of these faces. Open the Boundary

Conditions dialog box by selecting Simulation: Settings ![]() Boundaries

Boundaries ![]() .

For this example all boundaries need to be of type tangential.

This fact is important for the subsequent magnetostatic calculation, because

it means that the magnetic flux has only tangential (i.e. no normal) components

at the boundaries. For the stationary current problem the current ports

force the boundary conditions locally to be normal, which means that the

current field has only normal components at the current ports. Thus activate

the Apply in all directions checkbox

and choose tangential e, h or j

from the Type drop-down list.

.

For this example all boundaries need to be of type tangential.

This fact is important for the subsequent magnetostatic calculation, because

it means that the magnetic flux has only tangential (i.e. no normal) components

at the boundaries. For the stationary current problem the current ports

force the boundary conditions locally to be normal, which means that the

current field has only normal components at the current ports. Thus activate

the Apply in all directions checkbox

and choose tangential e, h or j

from the Type drop-down list.

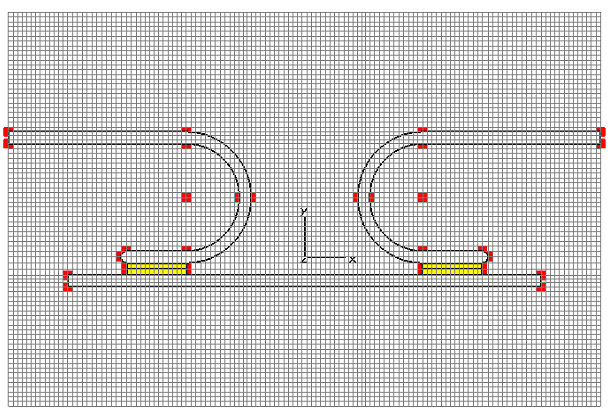

Next, you may define a symmetry condition for the XY plane. This will reduce the problem size by a factor of 2, so symmetry conditions should always be defined, if possible. Because currents and electric fields will be tangential and magnetic fields will be normal to the XY plane, you should select a magnetic symmetry plane inside the Symmetry Planes tab. Finally confirm with OK,

|

|

|

Please note: In particular, for coupled problems between the stationary current solver and the magnetostatic solver, normal and tangential symmetry planes are not recommended, Instead, the electric and magnetic symmetry planes should be used. They correspond to a Perfect Electric Conductor (PEC) for the electric boundary condition and a Perfect Magnetic Conductor (PMC) in case of the magnetic boundary condition.

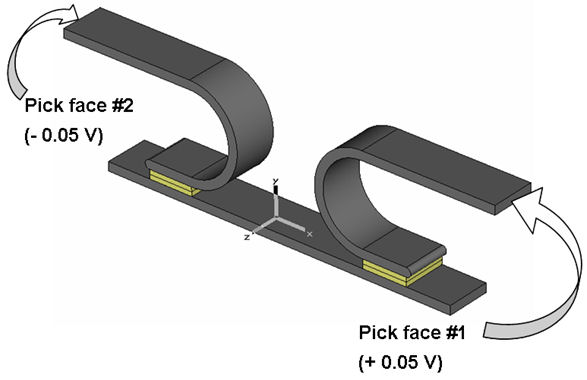

Before the solver can be started, the driving sources

need to be defined. In this tutorial, two current ports on the faces of

the contact springs are necessary to feed the structure with a homogeneous

distributed current density. Enter the current port definition mode (Simulation:

Sources and

Loads ![]() Current

Port

Current

Port ![]() ) and click on the right face at the upper X-boundary (face#1).

) and click on the right face at the upper X-boundary (face#1).

Once the position is defined via the face pick, the dialog opens and the Potential value of the port is requested. Enter the value 0.05 for the Potential of the first port and confirm with OK.

Then enter the current port definition mode again and pick face #2 at the lower X-boundary in order to define the second port. Enter a Potential value of -0.05 for this port:

|

|

|

Both faces are highlighted with colors corresponding to the potential values, when the Current ports folder in the navigation tree is selected.

Before starting the solver, let's have a look at the mesh used for the calculation. In this tutorial we will employ the hexahedral solver. Please note that the steps to employ the tetrahedral solver are completely identical. To keep this tutorial short, we will restrict the workflow description of the coupled simulation to the hexahedral solver and refer to the CST EM STUDIO Workflow & Solver Overview manual for more details on the tetrahedral solver.

Please switch the mesh type to Hexahedral via Simulation: Mesh

![]() Global

Properties

Global

Properties ![]() Hexahedral

Hexahedral ![]() . The Mesh Properties

dialog box opens automatically. The project template should have set the

Lower mesh limit to 20 and the

Mesh line ratio limit to 50.

Click OK to confirm the Hexahedral mesh settings and to close

the dialog box. The hexahedral mesh is generated automatically. Now activate

the mesh view via Simulation:

Mesh

. The Mesh Properties

dialog box opens automatically. The project template should have set the

Lower mesh limit to 20 and the

Mesh line ratio limit to 50.

Click OK to confirm the Hexahedral mesh settings and to close

the dialog box. The hexahedral mesh is generated automatically. Now activate

the mesh view via Simulation:

Mesh ![]() Mesh View

Mesh View ![]() .

Select Z Normal from the Mesh ribbon or z

key to obtain a view as depicted below. Apparently, the default

mesh is quite coarse:

.

Select Z Normal from the Mesh ribbon or z

key to obtain a view as depicted below. Apparently, the default

mesh is quite coarse:

For the circuit breaker tutorial, it is advisable to

adjust the mesh properties. Therefore, enter Mesh

Properties dialog box again (Simulation:

Mesh ![]() Global Properties

Global Properties

![]() ). In order to refine the mesh globally set the Lower

mesh limit to 60.

). In order to refine the mesh globally set the Lower

mesh limit to 60.

Finally, confirm with OK and observe the mesh. Please note that this setting leads to a transverse spatial resolution of the conductor with 3 mesh cells, which is sufficient for this tutorial.

Finally close the Mesh view via the Close Mesh View button in the Mesh ribbon.

Configure the stationary current solver

In case you wish to analyze only the results of the stationary

current solver, you can simply enter the stationary current solver dialog

box (Simulation: Solver ![]() Start Simulation

Start Simulation

![]() ),

check your settings and press Start

to the run the simulation.

),

check your settings and press Start

to the run the simulation.

In this tutorial, we would like to use the conduction current density field resulting from the stationary current solver run as a source field for a magnetostatic calculation. That's why it is NOT necessary to start a stand-alone stationary current solver run. The stationary current solver will be started automatically by the magnetostatic solver if a coupled simulation is required. This will be described in the next section.

Please note that in case of a coupled simulation (using the current density field as source for the magnetostatic solver), the stationary current simulation inherits all settings from the magnetostatic solver setup (e.g. the Mesh type and the Accuracy). Only Special settings (available via the Specials button in the Stationary Current Solver Parameter dialog box) will be taken into account. Moreover, the stationary current simulation itself does not perform an adaptive mesh refinement when coupled to the magnetostatic simulation.

Please recall that current loops have to be closed when used as source for the magnetostatic solver. Otherwise the problem is not solvable in the magnetostatic context, because Ampere's Law is violated. In combination with the conduction current density field, this means that the circuit has to be closed either via the boundaries (as in the present example) of via a current wire or PEC solid.

For our purposes, everything is set up correctly. We do not need to change the settings of the stationary current solver. The next step will be to configure the magnetostatic solver settings.

To run a magnetostatic calculation, the simulation type

has to be switched to Magnetostatic. Therefore, select Home:

Simulation ![]() Start Simulation

Start Simulation ![]() M-Static Solver

M-Static Solver

![]() .

This will also change the layout of some tool bars, which are now adjusted

to magnetostatic settings, but it will not change any of the settings

made by you in the previous steps. Now open the magnetostatic solver dialog

box by clicking again on the Start Simulation

button (Home:

Simulation

.

This will also change the layout of some tool bars, which are now adjusted

to magnetostatic settings, but it will not change any of the settings

made by you in the previous steps. Now open the magnetostatic solver dialog

box by clicking again on the Start Simulation

button (Home:

Simulation ![]() Start Simulation

Start Simulation ![]() ).

To complete the source definition, activate the checkbox Precompute

stationary current field. Finally press Start

to calculate the magnetic fields for a precomputed current distribution.

).

To complete the source definition, activate the checkbox Precompute

stationary current field. Finally press Start

to calculate the magnetic fields for a precomputed current distribution.

A progress bar will appear, which keeps you informed of the current solver status. First, the current fields from the stationary current solver will be computed and then the actual magnetostatic solver run will be performed.

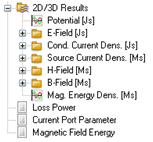

Congratulations, you have successfully simulated the circuit breaker! Let's look at the calculated fields and resistance of the structure. You will notice that some new entries have appeared in the navigation tree:

Please note that the numerical results might differ slightly depending on the operating system and the architecture of the machine with which they were computed.

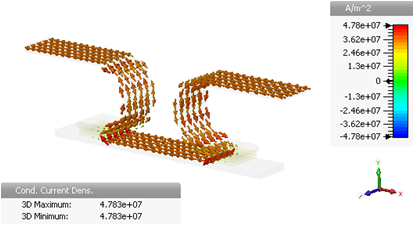

First let's have a look at the results from the stationary current simulation. Open the 2D/3D Results folder from the navigation tree and select the Cond. Current Dens. [Js] folder:

For a closer examination, you can increase the number

of plotted arrows, which accessible under 2D/3D Plot:

Plot Properties ![]() Properties

Properties ![]() (or from context menu). There, you can use the two sliders in the Objects frame to adjust the plot properly.

Please note that this setting has no influence on the accuracy of the

calculated fields; it only influences the visualization.

(or from context menu). There, you can use the two sliders in the Objects frame to adjust the plot properly.

Please note that this setting has no influence on the accuracy of the

calculated fields; it only influences the visualization.

Another result is the total Loss Power inside the calculation domain. Because this result is just a number, it is shown in a text viewer that appears after selecting the corresponding entry from the navigation tree with a double-click. When all modeling steps match the problem specifications, the loss power should be exactly equivalent to the value printed below:

Loss Power: 6.845811e+001 W

Because the total voltage drop has been defined with the current ports, the resistor of the model can be calculated from the total Loss Power, P:

![]()

With U = 0.1 V and a power of P = 6.8458e+001 W, the resistor calculates to:

![]()

The respective current value is derived as:

![]()

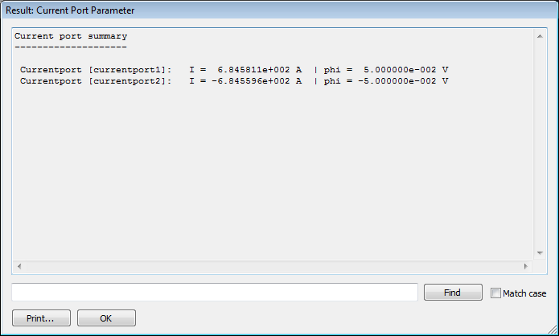

This can be validated by observing the Current Port Parameter entry, also accessible via the navigation tree:

These values differ slightly from those derived from the loss-power; this results from the previously defined solver accuracy of 1e-6. To obtain a more precise solution, a better accuracy (e.g. 1e-12) should be chosen for the stationary current simulation, of course, at the cost of a more time-consuming calculation.

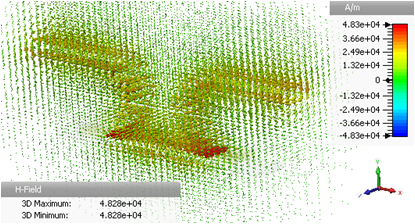

After this introduction to the result types of the stationary

current solver, let's now have a look at the results from the subsequent

magnetostatic calculation. The distribution of the magnetic field is of

primary interest. Therefore, select 2D/3D

Results![]() H-Field from the navigation

tree for a visualization of the magnetic field.

H-Field from the navigation

tree for a visualization of the magnetic field.

A static field calculation is mainly affected by two sources of numerical inaccuracies:

Numerical errors introduced by the iterative linear equation system solver.

Inaccuracies arising from the finite mesh resolution.

In this section, we provide hints on how to handle these errors and how to obtain highly accurate results.

CST EM STUDIO uses an iterative linear equation system solver to solve the discretized field problem. This means that the iterative solver will stop a calculation when a given accuracy has been reached. For most applications, the accuracy setting of 1e-6 is sufficient. In this case, the accuracy needed to be higher because the subsequent magnetostatic calculation required very accurate current fields.

Inaccuracies arising from the finite mesh resolution

are usually more difficult to estimate. The only way to ensure the accuracy

of the solution is to increase the mesh resolution and recalculate the

results. When the results do not significantly change with increasing

mesh density, convergence has been achieved. The above example used a

modified default hexahedral mesh. The easiest way to test the accuracy

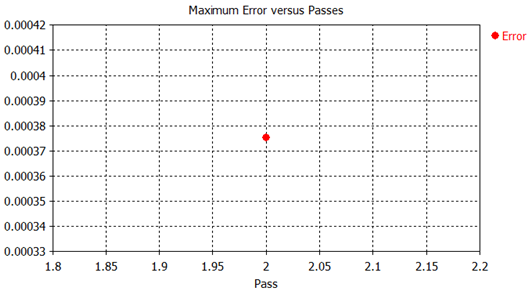

of the results is to use fully automatic mesh adaptation that can be switched

on by checking the Adaptive mesh refinement

option in the solver control dialog box. When you start the magnetostatic

solver again, stationary current and magnetostatic simulations will be

performed alternately. After the mesh adaptation procedure has finished,

you can visualize the maximum difference of the energy error for two subsequent

passes by selecting 1D Results![]() Adaptive Meshing

Adaptive Meshing![]() Error

from the navigation tree:

Error

from the navigation tree:

As evident in the above plot, the maximum energy deviation between the first and second pass is very low, indicating that the calculation with the first mesh already produced quite accurate results.

Please note that in a stand-alone stationary current simulation an automatic adaptive mesh refinement can be performed also for the Stationary Current solver run. The error plot will then inform you about the difference of the loss power error for two subsequent passes.

Congratulations! You have just completed the stationary current tutorial that should have provided you with a good working knowledge of how to use the stationary current solver in combination with the magnetostatic solver. The following topics have been covered so far:

General modeling considerations, using templates, etc.

Model a circuit breaker using the curve line, the curve arc, the trace from curve, the extrude, the brick and the transformation tool.

Define boundary and symmetry conditions.

Define current ports.

Apply changes to the automatically generated mesh.

Configure the stationary current solver.

Define the current density field as a source for the magnetostatic solver.

Start the magnetostatic solver.

Visualize the current density fields.

Calculate the models resistance.

Visualize the magnetic fields.

Ensure accurate and converged results by using the automatic mesh adaptation.

You can obtain more information for each particular step from the online help system that can be activated either by pressing the Help button in each dialog box or by pressing the F1 key at any time to obtain context sensitive information.

In some instances we have referred to the CST EM STUDIO Workflow & Solver Overview manual that is also a good source of information for general topics. In addition to this tutorial, you can find additional stationary current calculation examples in the Examples folder in your installation directory. Each of these examples contains a Readme item in the navigation tree that provides more information about the particular device.

And last but not least: Please visit one of the training classes, held regularly at a location near you. Thank you for using CST EM STUDIO.