Layers Stackup

Check Layout Stackup

Stackup

All PCBs have got a certain layer stack with a particular number of

layers. Although the number of layers is normally defined in the PCB design

input files, the corresponding layer stack itself (the so called

technology) is often not. If the technology

is defined in the PCB design input file(s) it will

be automatically imported during the EDA import. If the technology is not defined,

then certain default values will be used during the import and since the

stack up technology has a big influence on the high frequency behavior,

it should be reviewed after a PCB import in any case. The

Stackup Manager shows all layers at a glance:

Some of the parameters in the tabular view can be edited. This is possible

by double-clicking on the corresponding item and after that by entering

the new value or changing the selection in the appearing pull-down menu.

Certain parameters like Number

(third column) can’t be changed because they are set automatically.

Number of layers: Displays

the number of all conductive layers in the stack up.

Board thickness: Displays

the overall thickness of the PCB. The value depends on how the thickness

of the dielectric layers is interpreted. There are two different options

which can be selected in the field Prepreg.

Length units: Defines the unit

for all geometric length values.

Total thickness: The total

thickness is the sum of the Board thickness

and additional, artificial layers. There are two kind of artificial layers:

Enclosure and Mirror

Plane which are explained at the bottom of this page (see Create

New Layer).

Prepreg: Defines how the thicknesses

of the dielectric layers are interpreted. There are two possibilities:

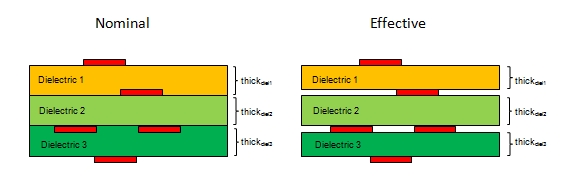

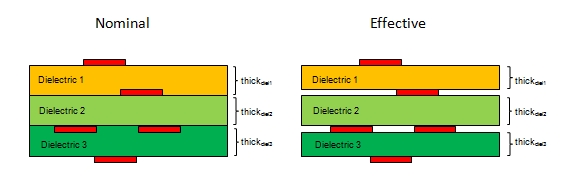

Effective or Nominal and the difference is explained in the figure

below:

In case of Nominal

the thickness of the dielectric layers are interpreted from the lower

dielectric interface to the upper dielectric interface. The conductive

structures of a signal laying along a dielectric interface are impressed

in either the dielectric layer above

or below. This can be chosen within

the column Fill. The overall board

thickness is the sum of all dielectric layers plus the two signal layers

at the top and bottom of the board. No inner signal layer contributes

to the board thickness. A disadvantage of the Nominal

interpretation is that the distances between two conductive layers are

not given directly.

In the case of

Effective the thickness

of a dielectric layer specifies the distance between the attached conductive

layers. The filling of the void space inside the conductive layers is

not fixed by the given data. The filling actually happens through flow

processes from the adjacent dielectric substrates during the manufacturing

process. Naturally the nature of the dielectric layer (Core

/ Prepreg) determines how the

void filling happens. Here, the program automatically fills the void space

according to the above / below specification inside the column Fill.

The overall board thickness is the sum of all dielectric and all signal

layer. The advantage of the Effective

interpretation is that the distances between two conductive layers are

given directly by the thickness of the corresponding dielectric layer

in between.

Most of the EDA design tools provide the dielectric layer thickness

data according to the

Effective specification.

But it is recommended to assure the setting for every new PCB project,

because the interpretation influences the high-frequency behavior of the

layout.

Create LDF File...: Offers

the export of the current layer stack up definition into a Layer

Definition File.

Read LDF File...: Offers the

import of an existing Layer Definition

File. When reading a LDF

file, the number of layers are automatically checked the user is prompted

if the number of layers mismatch.

Layer Name: Includes the name

of the layers which are also displayed in View Options Window. The fields inside this

column can be edited.

Type: There are three types

of layers: a dielectric type called

Dielectric, and two conductive

types: Signal and Plane.

The fields inside this column actually can not be edited. But in case

of a conductive layer, there is the possibility to switch between the

default setting Signal and the

optional setting Plane.

Transform to Signal

and Delete Areas

Sometimes it is useful that all non-conducting areas on a conductive

layer with different signal structures (traces, areas and vias) can be

filled with metal. This can be done in a three-step procedure which is

explained in the following example. The figure below shows a metallic

layer with two bigger drill holes at the top and the bottom side. The

layer should be repaired by removing the two drill holes.

Step 1:

The corresponding layer type in the

Stackup Manager has to be switched to Plane

as shown in the figure below:

After doing so, two additional buttons called Transform

to Signal and Delete Areas are automatically activated. Furthermore,

the last two columns Spacing and

Signal Name are activated. There

is a default Spacing value of

7.87 mil (= 0.2 mm) and the new

metallic structure has been given the default name GND.

The Main View

shows the new filled metallic layer in overlap with the old structures:

Step 2:

Now, all areas from the old layer definition shall be removed. This can

be done by pressing the Delete Areas

button. After doing so the program informs the user on the number of deleted

areas and after pressing OK,

the new layer can be seen in the Main

View:

.

The drill holes has been removed but now, all signal

vias (and in case of existing traces, traces too) are electrically connected

to the new metallic structure with the signal name GND.

Step 3:

In order to isolate the still existing traces and vias which belong to

other nets than GND, the Transform to Signal button has to be

pressed. After doing so, the non-GND

vias are isolated by the given spacing distance again as shown in the

figure below:

Number: Displays the number

of the metallic layer. The fields inside this column can not be edited.

Material: Displays the material

of the corresponding layer. The fields inside this column can be edited.

Thickness: Displays the thickness

of the layers. In case of a dielectric layers, this value is interpreted

differently according to the settings in the field Prepreg.

The fields inside this column can be edited.

The minimum thickness of any inner

dielectric must be bigger than the sum of the adjacent signal layers.

If this condition is violated an error message will be prompted.

Conductivity: Displays the

conductivity for the metallic layers. The fields inside this column can

be edited.

Permittivity: Displays the

relative permittivity of the dielectric layers. The fields inside this

column can be edited.

Loss Angle tan(): Displays

the loss angle of the dielectric layers. The fields

inside this column can be edited.

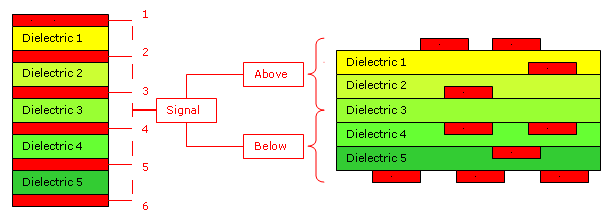

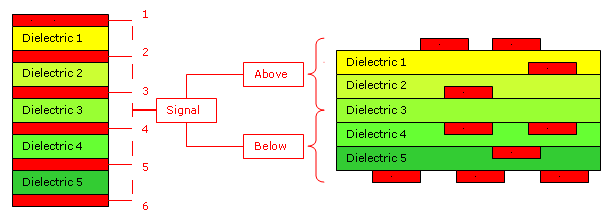

Fill: Determines if a trace

or an area on a signal layer shall be embedded into the dielectric above or below the corresponding dielectric interface.

This has a direct influence on the mutual distance between the single

signal layers as the following image illustrates.

The left side of the picture shows a layer stack where

each signal layer is separated from the other signal layers by exactly

one dielectric layer in-between. At the right side of the picture the

resulting geometry is shown if the top three signal layers are of fill

type Above and the bottom three signal layers are of fill

type Below. In order to give an example: signal layer 1

is placed on top of dielectric layer 1 and embedded into the environment dielectric

(e.g. air). Signal layer 4 is placed on the bottom of dielectric layer

3 and embedded into dielectric layer 4.

Note: The interpretation

of the thickness of the dielectric layers is determined by the settings

inside the field Prepreg.

At the right hand side of the Layer Stackup table there is a list of

buttons enabling a convenient handling of the layers inside the table:

Create New Layer: Will be explained

below

Copy Selected Layer: Allows the user

to copy an existing layer

Paste Selected Layer: Allows the user

to paste the previous copied layer

Delete Selected Layer: Deletes the selected

layer

Move Layer Up: Moves the selected layer

upwards

Move Layer Down: Moves the selected

layer downwards

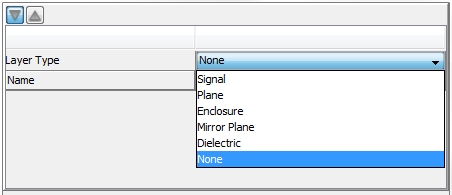

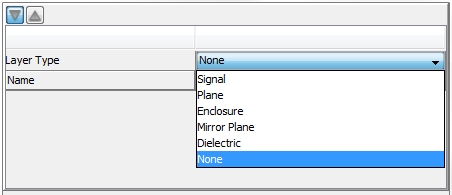

Create New Layer: Pressing this icon

will open the following dialog box:

The dialog box allows the creation of different types of layers:

Signal

Plane

Enclosure

Mirror

Plane

Dielectric

Enclosure:

An enclosure layer is similar to a signal layer: any number of enclosure

layers can be added to the layer stackup, separated by dielectric layers,

of course. The difference to signal layers is, however, that enclosure

layers lie outside the board geometry, above the top layer or below the

bottom layer of the board. An enclosure layers may include any arbitrary

conductor geometry including areas, traces or vias. In this way one is

able to replicate metallic enclosures that cover printed circuit boards.

Mirror Plane:

A mirror plane is a perfectly grounded infinitely expanded metallic layer.

Mirror planes are not subdivided into finite elements for modeling and

simulation but treated in an analytical way (Green’s functions)

by using mirror charges or mirror currents. That is the most effective

procedure to deal with large ground reference planes. Of course, all capacitances

and inductances between the PCB, any enclosure and the mirror planes are

automatically considered. A maximum number of two mirror planes can be

defined only.

Stackup

Stackup