This page contains a list of the most important warning and error messages in the context of source, boundary and material modeling together with a detailed explanation of the meaning and proposal for handling and resolution.

All degrees of freedom inside the port plane lie inside metal material, so that no mode pattern can be calculated. Please check whether the background material is defined as PEC or the port is located inside a metal object.

In case of a multi-conductor port usually TEM or QTEM modes are of interest. Depending on the dimension of the waveguide port and the upper limit of the global frequency range, there might also occur higher order propagating modes in addition. Usually this is not intended and these modes can be stopped from propagating by lowering the upper frequency limit. In principle it is also possible to reduce the port size, but this has to be done very carefully in order to still sufficiently cover the mode patterns of the relevant TEM and QTEM modes. In case that the higher order propagating modes are intended as e.g. box modes, the number of modes should be increased to consider these modes correctly for simulation.

In case of a multi-conductor port usually TEM or QTEM modes are of interest. Depending on the dimension of the waveguide port and the upper limit of the global frequency range, there might also occur higher order evanescent modes. Usually these modes have no important influence on the simulation, because they are decaying over a very small distance. However, in case that their damping constant is small their influence cannot be neglected anymore. By lowering the upper frequency limit these modes will be damped more intensively. In principle it is also possible to reduce the port size, but this has to be done very carefully in order to still sufficiently cover the mode patterns of the relevant TEM and QTEM modes. In case that the higher order evanescent modes are intended as e.g. box modes, the number of modes should be increased to consider these modes correctly for simulation.

This warning is shown when some propagating TE or TM modes are not considered in the simulation. Usually this is not intended and the modes could be taken into account by increasing the number of modes. In case of missing degenerated modes (sharing the same propagation constant) this is even more important to provide an accurate simulation result.

When the calculated field pattern at the port is a six-component mode, which can not be decomposed into two or more degenerated modes, this warning will be generated. Typically this is caused by incorrect structure modeling such as a microstrip transmission line where the ground plane does not intersect the port. Please check your port setup.

Although expected for a multiconductor port, one or more modes could not be classified as (Q)TEM at some frequency point. This usually happens at higher frequencies when longitudinal field components become stronger. The modes are classified as TE/TM or hybrid in this case. Consider to decrease the upper frequency limit.

At inhomogeneous ports it is necessary to track the mode pattern over frequency in order to provide correct scattering parameters. However, this is only possible if the mode patterns vary not too much between the lower and upper frequency limit. Furthermore, mode propagation constants might interchange over frequency such that the corresponding mode cannot be found anymore. In this case it might be necessary to increase the number of modes.

The inhomogeneous port accuracy enhancement can compensate errors introduced by frequency dependent mode patterns. However, this is only possible if the mode patterns vary not too much between the lower and upper frequency limit. If this warning is issued please consider decreasing the upper frequency limit or splitting the frequency range in higher and lower bands.

At inhomogeneous multipin ports QTEM modes are combined to satisfy the specified potential set definition. If the propagation constants of the modes differ too much they cannot be considered as degenerate anymore and they should not be combined.

To create a multpin port mode that satisfies the specified potential settings it is necessary to linearly combine the existing degenerated TEM or QTEM modes. If the mode calculation frequency is very low not all modes may be available. Consider increasing the mode calculation frequency in the specials dialog of the time domain solver or adjusting the global frequency range.

It is important that the number of defined potential sets equals the number of degenerated QTEM or TEM modes in the waveguide. If not a large part of the field may propagate in the unconsidered mode patterns. The waveguide port boundary still treats these fields internally but they will not contribute to the scattering matrix and may therefore lead to an inaccurate energy balance.

The defined potential sets should result in linear independent field patterns, e.g. the “even” and “odd” modes in a three conductor port. Otherwise the fields at the port cannot properly be decomposed into mode amplitudes. Please check whether the potential set definition is meaningful or consider treating the port as single-ended.

This warning is shown when a multipin port area has some decoupled mode regions, so called cavities. This might happen either by an incorrect port setup or by electric transversal port boundary conditions which creates cavities between themselves and the outer port conductor. In the latter case changing the boundary conditions to magnetic can remove these unwanted cavities.

It is important to consider all propagating modes in the simulation, since those parts of the fields attributed to unconsidered modes will be reflected at the Floquet port boundary. This usually may lead to inaccurate S-parameters. Please include all propagting modes by increasing the number of modes considered at the Floquet port in the Settings for Floquet Boundary dialog.

In order to simulate conductive material, the mesh has to be refined such, that the field variation (e.g. skin depth) is sufficiently discretized. This might lead to an extremely fine mesh representation for highly conductive materials. For these kind of materials the "lossy metal" model should be applied, which takes into account the skin effect without refining the mesh. However, if the skin depth is larger than the metal thickness and a radiation effect through the metal is of importance, the “lossy metal” model cannot be used anymore and type "normal" should be selected. This is also true for materials with very low conductivity where the "normal" material type offers a more accurate simulation result than the "lossy metal" surface model.

The two warning messages indicate which material type selection should be preferred. Please find a more detailed description on these and other material types on the Material Overview page.

Some discrete ports or lumped network elements were found which are not connected to any good conductor, for instance "floating" some distance away from a conductor due to modelling tolerances. Especially at low frequencies, results then can differ from what is expected, since the connection to the remaining three-dimensional representation of the circuit is uncertain. Please zoom in to inspect the connectivity of the network elements, and create them again if necessary (preferably pick a part of the conductors the network element should be connected to).

The check for floating elements considers the end points of edge lumped network elements. This also the case for the face ports and face lumped network elements: they have an alternative edge lumped network element associated with them which is used by solvers that do not support the face type lumped network elements. For the sake of simplicity and performance of the connectivity check, these associated edges will be used for the face lumped network elements. For each of their end points, the check tries to find a conductor body that contains the point. PEC and lossy metal solids are considered as good conductors, as well as normal materials with a conductivity higher than 1000 S/m.

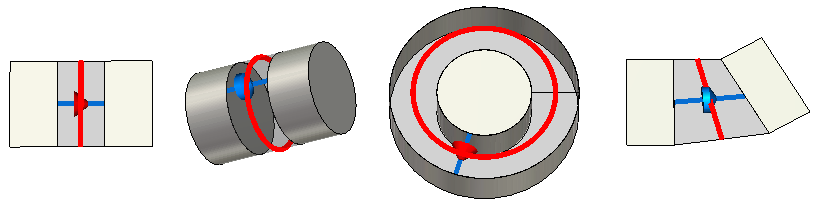

The error message is displayed if the shape of the face lumped network elements is not supported or not recognized, for instance due to modelling accuracy. Rectangular, cylinder-barrel and radial lumped network elements are supported. They are illustrated by the first three lumped network elements in the picture below. Please delete and re-create the lumped network elements so that their shape is either rectangular, cylinder-barrel, radial like, or use straight edge lumped network elements.

from left to right: a rectangular discrete port, a cylinder-barrel lumped

network element, a radial discrete port, a lumped network element of different

shape

The general purpose frequency domain solver with tetrahedral mesh verifies the dimensions of the discrete face ports to check if the mesh representation of the discrete face port agrees with how the source was modeled. In order to apply one of the face port definitions shown in the picture above, the characteristic dimensions must be known to the solver and the mesh needs to be consistent with that data.

One reason for this error message is an overlap of the discrete face port with solids made of PEC or lossy metal material. They effectively reduce the area of the discrete face port.

Another case where this error message is shown may occur if symmetry conditions are present and the face port touches the symmetry plane without being symmetric to the symmetry condition. Please enlarge the discrete face port in that case.

The two examples below show the unsupported case at the top and the recommended solution at the bottom: