Aspherical Lenses

Aspherical Lenses

Aspherical lenses are lenses with complex curved surfaces, such as where the radius of curvature changes according to distance from the light beam axis.

Spherical lenses are subject to aberration and therefore cannot concentrate all the light into one point. Aspherical lenses, however, offer excellent aberration correction performance, providing superior resolution performance, even with compact optics composed of a small number of elements.

Based on our long experience in aspherical fabrication, we provide optimal solutions for various customer needs.

High-precision ground and polished aspherical lenses

The surfaces of spherical lenses made of optical glass are ground into aspherical shapes by grindstones revolving at high speeds.

Utilizing expert craftsmanship, we established an automatic system for high-speed aspherical grinding with nanometer-order precision.

In this process, the master can be formed into special aspherical surfaces, such as off-center parabolic curvatures, then the shape can be transferred to optical resin with the molding technique.

Nikon is especially good at this replica-forming technique, and applies it in manufacturing components for optical fiber communications and more.

High-precision grinding

After the grindstone is moved to grind the glass down to an aspherical curvature, the surface is polished.

This technique provides exceptional precision, and is used to manufacture aspherical lenses for steppers.

Our precision grinding technology is unsurpassed in a range of applications demanding ultra-precision, such as for making aspherical lenses for projection lenses of steppers and aspherical metal molds.

Precision Glass Mold (PGM) aspherical lenses

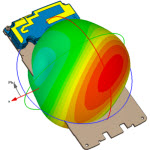

In precision glass molding, optical glass is softened by heating, then shaped in an aspherical mold made of special heat-resistant material.

We have developed a special molding technique effective for medium- to large-diameter aspherical lenses, which were previously considered to be difficult to mold.

This technology is widely utilized in the manufacture of aspherical lenses for lenses for film-based and digital cameras.

PGM

The glass lens material is pressed at high temperature and pressure in the aspherical-shaped mold.

PAG (Plastics on Aspherical Glass) hybrid lenses

The term Plastics on Aspherical Glass, or PAG, generally refers to the method used to fabricate hybrid aspherical lenses combining glass and plastic.

UV-curable resin is injected between the spherical glass and the aspherical metal mold, and irradiated with UV to form a glass-resin hybrid aspherical lens.

Nikon has developed its own plastics and molding technology for PAG, and now manufactures large-diameter, high-precision lenses with large aspherical lens surfaces in volume and at low cost.

PAG

UV-curable resin is injected between the spherical glass lens and the aspherical metal mold,

then irradiated with UV light to form hybrid lenses.

Nikon has developed original technology for each key factor -- including materials, fabrication and measurement -- to make possible these three methods of manufacturing aspherical surfaces.

By selecting the best method for each individual application, we can quickly meet the demand for a wide range of products, from ultra-precision custom designs to reasonably-priced volume items.