Solid or thin metal structures can be placed anywhere within the mesh, or modelling region. If they are coincident with the external boundaries, then they will take priority over the boundary conditions. An important feature of metal structures in CST MICROSTRIPES is that they are impenetrable to electromagnetic radiation. Even if a thin metal wall is defined as being lossy, no electromagnetic field will ever penetrate it. If the user wishes to define a lossy panel through which electromagnetic waves can pass, then a thin panel material must be used rather than metal (see Thin Panel Materials).

The 3D-TLM Simulator takes advantage of the impenetrability of metal to minimize computational resources. If a simulation contains solid metal blocks, then the Simulator will ignore the space inside the metal. It will allocate no cells to calculate the electromagnetic fields inside the solid metal. The user should therefore whenever possible, define areas of the mesh outside the region of interest (dead-space) as being solid metal. This is essential in waveguide simulations. Another example of its use is for horn antennas if the calculation of back scattering is unimportant. Filling the region behind the horn mouth with metal, and giving it a lossy surface to absorb incident waves, will save considerable time and memory.

For many applications metal bodies can be assumed to be perfectly conducting - in which case the surface impedance of the metal should be set to zero. For those cases where metal loss cannot be neglected, the loss can be specified in one of two ways; either by giving the metal conductivity and permeability, or by giving it a surface impedance.

Specifying the conductivity and permeability of a metal results in a frequency dependent loss. The metal properties are taken as independent of frequency, but the Simulator models the metal surface as a number of layers so that the frequency dependence of the skin-depth is reproduced. The metal surface is only modelled to a certain depth, so there is a lower frequency limit below which the loss is not accurate (but continues to decrease with frequency). This lower limit is about 1% of the maximum model frequency.

As stated before, even if the skin-depth reaches the physical thickness of a metal body, no electromagnetic field will penetrate it.

Modelling a metal surface in this way is computationally efficient. Each cell face resting on a metal surface requires only a fraction of the memory required by the cell itself.

If a surface impedance is specified rather than a conductivity, then a fixed, frequency independent loss results. This is appropriate in three circumstances:

• When no loss is required (surface impedance = 0)

• When only a narrow frequency band is of interest

• When an absorbing surface is required (as a load).

Metals with a surface impedance consume no computational resources at all - beyond storing the value of the impedance.

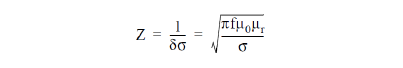

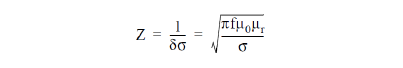

To model a metal with conductivity , and permeability over a narrow frequency band centered on f, the appropriate surface impedance is

A ‘metal’ surface covering the end of a waveguide or transmission line will form a matched load if its surface impedance matches the wave impedance in the guide or line. For example, an air-filled coax will be matched by a metal surface of impedance 377 Ohm. Note that this is the wave impedance, not the characteristic impedance of the line.

For a waveguide, the wave impedance is frequency dependent, and so can only be matched at one frequency by a fixed impedance termination. In this case the termination should be chosen to give a match at a frequency around the middle of the band of interest. For a TE mode this will typically mean an impedance of 500 Ohm. The Waveguide Utility can be used to get the appropriate impedance at the frequency of interest for a given waveguide size.

Ideally, different dielectric bodies should not occupy the same volume and metal or thin panel bodies should not occupy the same surface. The 3D-TLM Simulator will check to see if overlapping and ambiguous regions are included in the model if the tickbox ‘Allow different materials to overlap’ is unchecked on the Advanced dialog of the mesh definition dialog.

Metal bodies may always overlap dielectric bodies, in which case the region of overlap is taken to be metal. This is useful when metal parts are to be embedded in dielectric.