To prepare a model for simulation, the Build module of CST MICROSTRIPES divides the model and the space it occupies, into a large number of spatial elements or cells. These cells are small rectangular blocks arranged on a Cartesian mesh.

The 3D-TLM simulator requires that each cell is homogeneous, that is, the cell must be entirely empty or entirely filled with the same metal or dielectric material. This condition is met by means of the Build Automesher which aligns the cell-faces with the surfaces of the model. Failure to align the cell-faces with the model, results in the surfaces of the model effectively jumping to the nearest cell face.

The size of the largest and smallest cells in the mesh have a significant effect on the accuracy and speed of the simulation, and deserve careful consideration.

The 3D-TLM simulator considers the electromagnetic field to be uniform within each cell. It is therefore necessary for the cells to be small on the scale of distance over which the field varies. To achieve this, Build chooses the default cell-size to be 1/10 of the free-space wavelength at the requested maximum model frequency, or 5% of the model size, whichever is the smaller. If even one cell is made larger than this in any dimension, then the maximum frequency at which the results are considered valid will be reduced.

Of course, the field can vary over shorter distances - in the presence of dielectric or permeable materials, or where it is constrained to do so by the shape of the model. The Automesher always takes into account material properties, and reduces the cell-size within dielectric bodies.

Although reducing the cell-size increases the accuracy of the simulation, it also demands more computer resources - and it does this in two ways. Firstly and most obviously, a larger number of smaller cells are required to fill a given volume of space, and this increases both the run-time and memory requirement.

Secondly, the time-step of the simulation depends on the size of the smallest cell. If even one cell is made smaller than the others by (say) a factor of 5 in linear dimensions, then the time-step of the simulation will be reduced by the same factor. For the simulator to cover a given length of time will then take 5 times as many time-steps, and the computer run-time will be increased proportionately. For this reason, the Build Automesher has a minimum cell-size limit - which defaults to 1/10 of the default maximum cell-size.

For the purpose of determining the time-step, the precise definition of ‘smallest cell’ is a little complicated, depending on the two smallest out of each cell’s length, breadth and height, and on the properties of the material within the cell. To a fair approximation however, it will take at least two time-steps for light to cross any cell in any direction - so that the time-step depends critically on the smallest dimension of any cell.

In summary...

The largest dimension of any cell limits the frequency range and the smallest dimension of any cell limits the time-step.

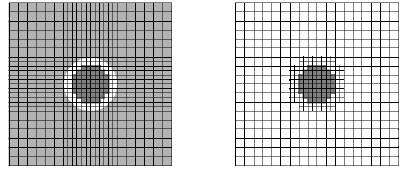

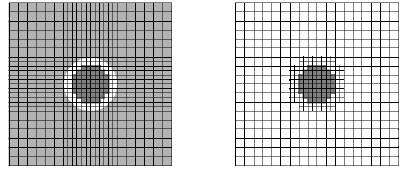

A consequence of having rectangular cells, is that any region of small cells must extend in a band across the entire mesh - as shown below on the left. This can result in an excessive number of cells and hence in an excessive computer run-time and memory requirement.

The number of cells can be reduced by combining, or lumping, groups of unnecessarily small cells into larger cells. This is shown below on the right, where groups of two or four cells have been lumped together. The result in this case is a fine mesh embedded in a coarser mesh. This arrangement, commonly met with in antenna simulation, is referred to as multigridding.

In this illustration the saving in cells is only about 27%, but in a three dimensional mesh the saving can be far greater.

To use lumped cells in CST MICROSTRIPES it is only necessary to select a maximum cell size. Build will then inspect the geometry and apply the most appropriate lumping up to the specified maximum cell size (which should not exceed 1/10 of the free-space wavelength).

The user should be aware that there is a considerable amount of internal checking that the 3D-TLM simulator must perform on any input files that contain lumped cells, and that this may take some time. The checking time, however, will be negligible compared to the reduction in simulation time achieved by using lumped cells.