![]()

![]()

Geometric Constructions and Solver Settings

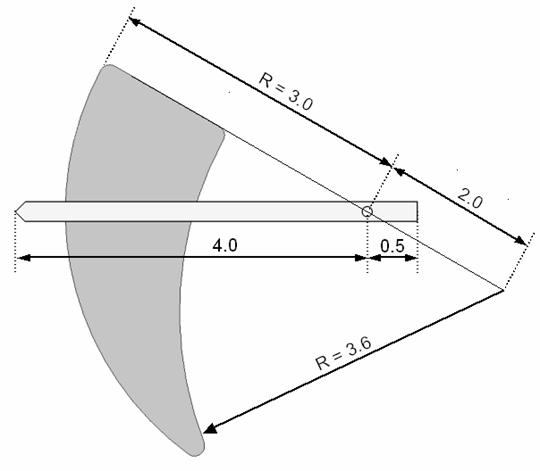

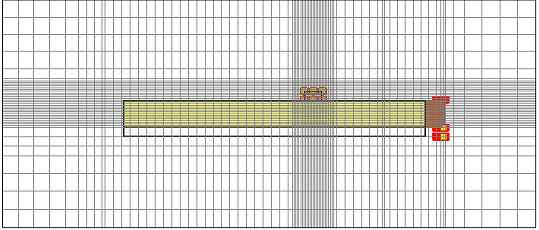

This tutorial deals with the simulation of a simple electrometer device that can be used for voltage measurements. The model used for the electrometer consists of three parts: the electrometer's scale, the ground and the pointer. The main dimensions of the electrometer device are shown in Figure 1.

Figure 1: The Model and its main dimensions

The results of interest are the capacitance and the torque for different angles of the pointer. A parameter sweep with a user-defined watch will be used for the simulation of the electrometer device. Finally, the results will be discussed.

We strongly suggest that you carefully read through the CST EM STUDIO Workflow & Solver Overview manual before starting this tutorial.

This tutorial demonstrates how to perform a capacitance calculation. It will guide you through the construction of a simple electrometer for voltage measurements. For details concerning geometrical constructions please refer also to the online help and the CST EM STUDIO Workflow & Solver Overview manual. Please note that the project file with the complete geometry is delivered with the installation and accessible from the Examples Overview (or the button Run Example at the beginning of this page).

After launching the CST STUDIO SUITE you will enter the

start screen showing you a list of recently opened projects and allowing

you to specify the application which suits your requirements best. The

easiest way to get started is to configure a project template which sets

the basic settings that are meaningful for your typical application. Therefore

click on the Create Project ![]() button in the New Project

section.

button in the New Project

section.

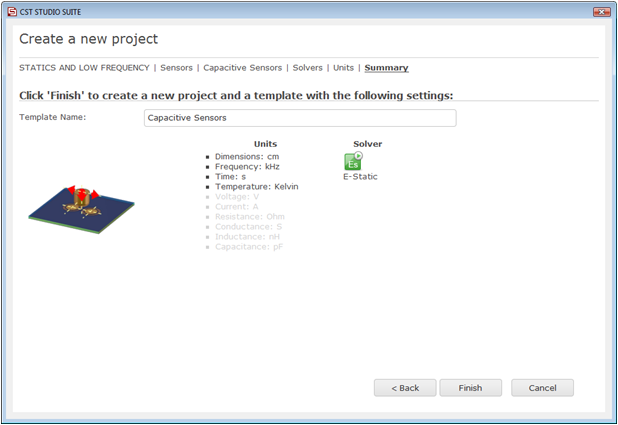

Next you should chose the application area, which is Statics and Low Frequency for the example in this tutorial and then select the workflow by double-clicking on the corresponding entry.

For the electrometer device, please select Sensors

![]() Capacitive Sensors

Capacitive Sensors ![]() E-Static

E-Static

![]() .

.

At last you are requested to select the units which fit your application best. In this tutorial all geometrical dimensions in this example are given in cm. Therefore select cm from the Dimensions drop-down list. For the specific application in this tutorial the other settings can be left unchanged. After clicking the Next button, you can give the project template a name and review a summary of your initial settings.

Finally, click the Finish button to save the project template and to create a new project with appropriate settings. CST EM STUDIO will be launched automatically due to the choice of the application area Statics and Low Frequency.

Please note: When you click again on File: New and Recent you will see that the recently defined template appears below the Project Templates section. For further projects in the same application area you can simply click on this template entry to launch CST EM STUDIO with useful basic settings. It is not necessary to define a new template each time. You are now able to start the software with reasonable initial settings quickly with just one click on the corresponding template.

Please note:

All settings made for a project template can be modified later on during

the construction of your model. For example, the units can be modified

in the units dialog box (Home:

Settings ![]() Units

Units ![]() ) and the solver type can be selected in the Home:

Simulation

) and the solver type can be selected in the Home:

Simulation ![]() Start Simulation drop-down list.

Start Simulation drop-down list.

The construction steps of the electrometers scale are based on the creation of two circles, extrusion of a planar curve to build a solid and blending the edges of the solid.

To create the first circle, select Modeling: Curves

![]() Curves

Curves ![]() Circle

Circle ![]() .

Now the circle creation mode is active allowing you to enter the circles

coordinates either by using the mouse or by keyboard input. When you press

the Shift+Tab keys simultaneously,

you can enter first the center point and then the radius numerically.

Alternatively you can directly enter the Circle

dialog box by pressing Esc. For

this example, create a circle with

.

Now the circle creation mode is active allowing you to enter the circles

coordinates either by using the mouse or by keyboard input. When you press

the Shift+Tab keys simultaneously,

you can enter first the center point and then the radius numerically.

Alternatively you can directly enter the Circle

dialog box by pressing Esc. For

this example, create a circle with

Center at X=0 and Y=0 and

Radius 3.0.

The preview of the circle is displayed in the Modeler

View with orange color according to the settings in the dialog box. After

all settings are confirmed with OK,

the circle color changes to blue and a new entry appears in the Navigation Tree under Curves

![]() curve1

curve1 ![]() circle 1.

circle 1.

To construct the second circle, select again Modeling:

Curves ![]() Curves

Curves ![]() Circle

Circle ![]() .

Create a circle with

.

Create a circle with

Center at X = 2 and Y = 0 and

Radius 3.6.

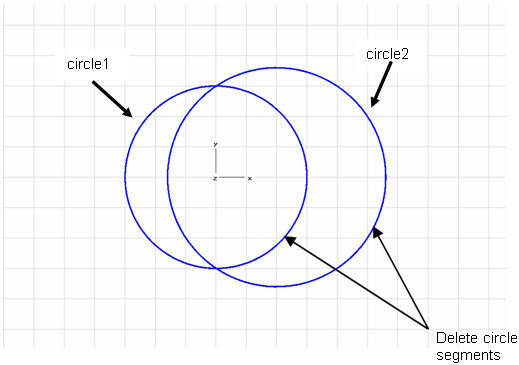

The two circles intersect. They are used for the next construction step to define an outline of a sickle-like structure. Therefore, one segment of each circle has to be deleted as shown below.

You can delete the two marked

circle segments by trimming the two circles and selecting the circle segments

you want to delete. Please select circle1 by either double-clicking on

the initially created circle in the Modeler View or by selecting Curves ![]() curve1

curve1 ![]() circle1 in the Navigation

Tree.

circle1 in the Navigation

Tree.

To start the trim action,

select Modeling:

Curves ![]() Curve Tools

Curve Tools ![]() Trim Curves

Trim Curves ![]() from the menu bar or use the shortcut #. Then select circle2

and confirm with the Return key.

Now the interactive trim tool highlights all curve parts that can be deleted.

Delete the curve segments shown in the previous screenshot by double-clicking

on the appropriate circle segment. Please check

the model against the screenshot below. To confirm the trim action, press

Return.

from the menu bar or use the shortcut #. Then select circle2

and confirm with the Return key.

Now the interactive trim tool highlights all curve parts that can be deleted.

Delete the curve segments shown in the previous screenshot by double-clicking

on the appropriate circle segment. Please check

the model against the screenshot below. To confirm the trim action, press

Return.

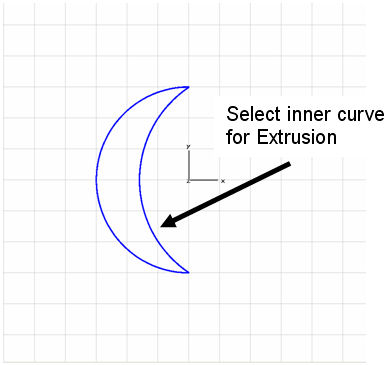

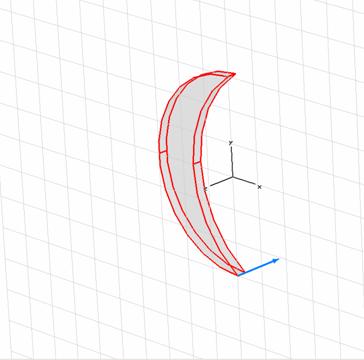

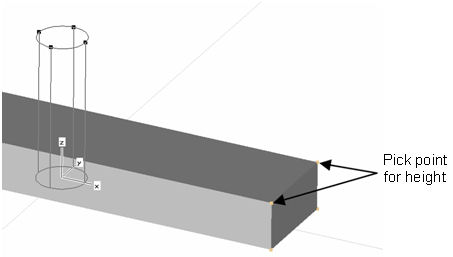

In the next construction

step, the sickle-like outline is used to create a solid. Therefore,

the curve defining the sickle-like outline is extruded. First, please

select Modeling:

Curves ![]() Curve Tools

Curve Tools ![]() Extrude

Curve

Extrude

Curve ![]() .

To define the profile for the extrusion double-click on the inner curve

item of the circle segment of the last created circle (circle2).

The Extrude Planar Curve dialog box opens, enabling you to set the extrusion

thickness, a twist angle and a taper angle. For this tutorial, just set

the Thickness to 0.3 and name

the solid scale. Press the Preview

button to ensure that the extrusion normal points in the negative z-direction.

A blue arrow indicates the direction of the extrusion normal as shown

in the picture below. If the extrusion normal points in the positive z-direction

you may have accidentally selected the wrong circle segment when extruding

the curve.

.

To define the profile for the extrusion double-click on the inner curve

item of the circle segment of the last created circle (circle2).

The Extrude Planar Curve dialog box opens, enabling you to set the extrusion

thickness, a twist angle and a taper angle. For this tutorial, just set

the Thickness to 0.3 and name

the solid scale. Press the Preview

button to ensure that the extrusion normal points in the negative z-direction.

A blue arrow indicates the direction of the extrusion normal as shown

in the picture below. If the extrusion normal points in the positive z-direction

you may have accidentally selected the wrong circle segment when extruding

the curve.

Before you can confirm your settings, the material properties of the new solid must be defined. Please select New Material... from the Material drop down list. In the New Material Parameters dialog box set the Material name to dielectric and the Type to Normal material. Next specify the dielectric constant by entering 10 in the Epsilon field and click the colored button to choose a contrasting color for the new material. Finally, press the OK button to store the materials parameters.

|

|

|

Back in the Extrude Planar

Curve dialog box press OK to

create the new solid. It will appear in the Navigation Tree under

Components ![]() component1

component1 ![]() scale. The initially created curve

items circle1 and circle2

are deleted automatically.

scale. The initially created curve

items circle1 and circle2

are deleted automatically.

If you closely examine the

created solid you may see that the edges of the solid which are based

on the initially created circles are not displayed as accurately as desired.

Therefore, for this tutorial the default triangulation accuracy should

be increased to visualize the model more precisely. Please select View:

Options ![]() View Options (Alt+V)

View Options (Alt+V) ![]() and increase the Triangulation

accuracy from the Shape Accuracy

tab by dragging the slider closer to the high

position.

and increase the Triangulation

accuracy from the Shape Accuracy

tab by dragging the slider closer to the high

position.

Please note: This view option has no influence on the calculation. The created solid is now displayed with a higher shape accuracy as shown in the picture below.

|

|

|

The next construction task

is to delete a part of the sickle-like shape. This can be accomplished

with the slice object by uv plane

feature. First, the working

coordinate system

(WCS) should be activated (Modeling:

WCS ![]() Local WCS

Local WCS ![]() ). Then perform a 90° rotation around

the u-axis of the local coordinate system by pressing Shift+u or selecting

Modeling:

WCS

). Then perform a 90° rotation around

the u-axis of the local coordinate system by pressing Shift+u or selecting

Modeling:

WCS ![]() Transform WCS

Transform WCS ![]() and then Rotate, U,

90.0 in the Transform dialog

box. Now the working plane intersects with the solid such that it

splits the solid into two parts of equal size.

and then Rotate, U,

90.0 in the Transform dialog

box. Now the working plane intersects with the solid such that it

splits the solid into two parts of equal size.

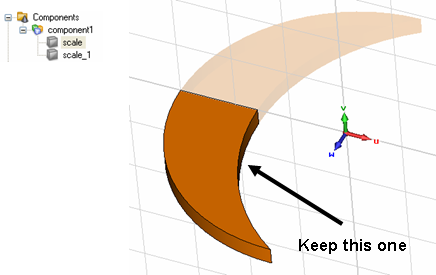

To perform the slicing, select

the shape component1:scale from

the Navigation Tree or double-click on it. Now you can slice the sickle-like

shape by either selecting Modeling:

Tools ![]() Shape Tools

Shape Tools ![]() Slice by UV Plane

Slice by UV Plane ![]() or by selecting Slice by UV Plane

from the context menu that appears if you press the right mouse button

in the Modeler View window. The sickle-like shape is now split into two

solids.

or by selecting Slice by UV Plane

from the context menu that appears if you press the right mouse button

in the Modeler View window. The sickle-like shape is now split into two

solids.

For the electrometers scale, only the original solid is needed; the new one (scale_1) has to be deleted. Please select this shape and delete it either by pressing the Delete key, by selecting Delete from the context menu.

The local coordinate system

will not be used for the following construction steps. Switch it

off by toggling the Modeling:

WCS ![]() Local WCS

Local WCS ![]() .

.

The next step is to rotate

the dielectric solid around the coordinate system's origin by a parameterized

value. Select the solid scale

and open the Transform Selected Object

dialog box by selecting Modeling:

Tools ![]() Transform

Transform ![]() Rotate

Rotate ![]() . The Operation

Rotate should be selected. Enter -angle

as the rotation angle around the z-axis. Make sure that the Shape

center option is deactivated. (If necessary, press the More>>

button to extend the dialog box.) After confirming with OK a new dialog

box appears and asks you to enter a value for the recently introduced

parameter. Set its value to 30

and enter a helpful description text before confirming with OK. The

recently defined parameter appears inside the Parameter

List window which is usually docked at the lower left part

of the user interface.

. The Operation

Rotate should be selected. Enter -angle

as the rotation angle around the z-axis. Make sure that the Shape

center option is deactivated. (If necessary, press the More>>

button to extend the dialog box.) After confirming with OK a new dialog

box appears and asks you to enter a value for the recently introduced

parameter. Set its value to 30

and enter a helpful description text before confirming with OK. The

recently defined parameter appears inside the Parameter

List window which is usually docked at the lower left part

of the user interface.

|

|

|

Next the three edges have

to be blended. To pick these edges, select Modeling: Picks ![]() Picks

Picks ![]() or use the shortcut e to activate

the Pick Edge Mode. The three picked edges are highlighted with a red

color. To apply the blending to these edges enter the Blend

Edges dialog box (Modeling:

Tools

or use the shortcut e to activate

the Pick Edge Mode. The three picked edges are highlighted with a red

color. To apply the blending to these edges enter the Blend

Edges dialog box (Modeling:

Tools ![]() Blend

Blend ![]() ).

Enter 0.1 to the Radius

text field and press the OK button

to apply a blend operation with radius of 0.1 cm to all three edges.

).

Enter 0.1 to the Radius

text field and press the OK button

to apply a blend operation with radius of 0.1 cm to all three edges.

|

|

|

|

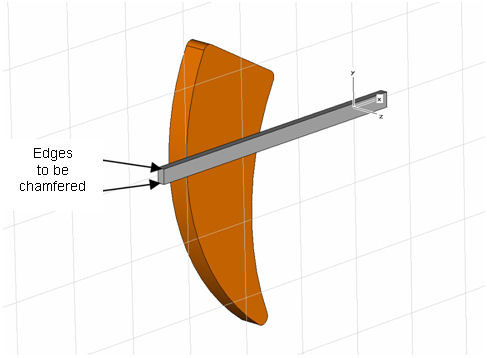

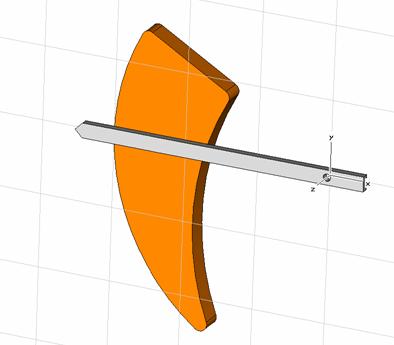

The construction steps of the electrometer's pointer are based on the creation of a brick, chamfering its edges, defining a cylinder and applying Boolean operations on intersecting solids.

Initially, a brick of PEC

material has to be created. Therefore, click on Modeling:

Shapes ![]() Brick

Brick ![]() to activate the brick creation mode. Use the Tab

key to enter the coordinates for the min/max corners and height numerically

or press Esc to enter the Brick dialog box immediately. Create

the brick with

to activate the brick creation mode. Use the Tab

key to enter the coordinates for the min/max corners and height numerically

or press Esc to enter the Brick dialog box immediately. Create

the brick with

First corner: X = -3.5, Y = -0.1 (Xmin, Ymin)

Second corner: X = 0.5, Y = 0.1 (Xmax, Ymax)

Height: Zmax = 0.1 (Zmin = 0)

Please change the name to pointer and the material of the brick to PEC by selecting PEC from the Material drop down list. Later in the modeling process, this will enable you to define potentials or charges to the pointer.

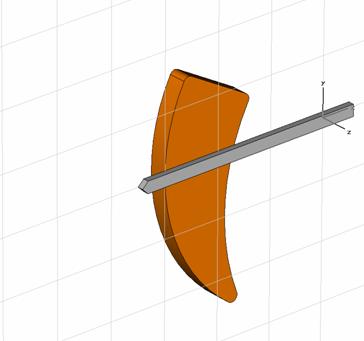

The new shape pointer

needs a spike for the visualization. This is accomplished by chamfering

two front edges (see screenshot above). First, the two edges have

to be picked (Modeling:

Picks ![]() Picks

Picks ![]() or shortcut e). Similar to the

blending of the edges of the electrometer's scale, the chamfering is applied

to the currently selected edges. Select Modeling:

Tools

or shortcut e). Similar to the

blending of the edges of the electrometer's scale, the chamfering is applied

to the currently selected edges. Select Modeling:

Tools ![]() Blend

Blend ![]() Chamfer Edges

Chamfer Edges ![]() and enter the Chamfer width of 0.1. Leave the Angle at 45.

Press OK to apply the chamfer

operation and to close the dialog box. The chamfered brick is displayed

in the screenshot below.

and enter the Chamfer width of 0.1. Leave the Angle at 45.

Press OK to apply the chamfer

operation and to close the dialog box. The chamfered brick is displayed

in the screenshot below.

The pointer features a hole

at the origin of the global coordinate system. This hole can be modeled

by defining a cylinder centered on the origin of the global coordinate

system. Please click on Modeling:

Shapes ![]() Cylinder

Cylinder ![]() to launch the Cylinder Creation Mode. Again use the (Shift+)Tab keys to

define

to launch the Cylinder Creation Mode. Again use the (Shift+)Tab keys to

define

the center at X = 0 and Y = 0 and

the radius 0.05.

The cylindric hole should

be as high as the pointer. To ensure this, pick a point (shortcut p or Modeling:

Picks ![]() Picks

Picks ![]() )

from the pointer, e.g. one of two proposed in the next screenshot.

)

from the pointer, e.g. one of two proposed in the next screenshot.

Now that the height is defined, you are requested to define the inner radius of the cylinder. Because no inner radius is needed for this cylinder, press the Esc key to leave the Cylinder Creation Mode. Finally, the Cylinder dialog box opens, enabling you to set the material properties of the cylinder. Please ensure that the Vacuum material is selected from the Material drop down list.

When you confirm with OK, the Shape Intersection dialog box will open and ask you how to handle the intersection with the pointer. Because the created cylinder models the axis hole, the cylinder should be cut away from the pointer. Check the Cut away highlighted shape radio button and confirm with OK.

|

|

|

For further simulation purposes

it is useful to have a small distance between the pointer and the scale.

This is, in particular, of interest, when the force or torque on the pointer

is computed. Otherwise the scale would influence and therefore distort

the result of the torque computation. To this end, select the pointer

and enter the transformation dialog box (Modeling:

Tools ![]() Transform

Transform ![]() Translate

Translate ![]() ) to enter a translation of 0.01

in the z-direction. When you switch to a frontal view, e.g. via View:

Change View

) to enter a translation of 0.01

in the z-direction. When you switch to a frontal view, e.g. via View:

Change View ![]() Left, you can see the pointer's distance from the scale:

Left, you can see the pointer's distance from the scale:

The last solid that must

be modeled is the ground. It will be constructed using the extrusion

tool. Pick the face (Modeling:

Picks ![]() Picks

Picks ![]() or shortcut f) of the

dielectric solid (scale) which

is located on the opposite side of the pointer. Then activate the extrusion

tool by selecting Modeling:

Shapes

or shortcut f) of the

dielectric solid (scale) which

is located on the opposite side of the pointer. Then activate the extrusion

tool by selecting Modeling:

Shapes ![]() Extrude

Extrude ![]() . Please name the solid ground,

set the Height to 0.1

and set the Material to PEC in the appearing Extrude

Face dialog box.

. Please name the solid ground,

set the Height to 0.1

and set the Material to PEC in the appearing Extrude

Face dialog box.

|

|

|

The structures modeling is now complete.

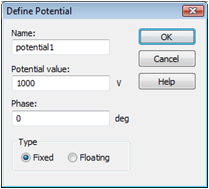

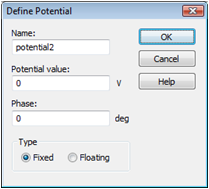

For proper function of the electrometer, a voltage source between the two PEC regions must be defined. This can be accomplished with two potential definitions.

Activate the potential tool (Simulation:

Sources and Loads ![]() Electric Potential

Electric Potential ![]() ), double-click on the pointer

solid and press the Enter key

to define the Potential value

of 1000V. Similarly, set the

ground potential to 0

V. Please note that the definition of the second potential is necessary

to calculate the capacitance matrix (only potentials will be considered

for the capacitance matrix). The screenshot below shows the structure

with the potential settings of the electrometer's ground and pointer.

), double-click on the pointer

solid and press the Enter key

to define the Potential value

of 1000V. Similarly, set the

ground potential to 0

V. Please note that the definition of the second potential is necessary

to calculate the capacitance matrix (only potentials will be considered

for the capacitance matrix). The screenshot below shows the structure

with the potential settings of the electrometer's ground and pointer.

Please note: All

PEC regions that are not assigned with a source will, by default, be given

a potential of 0 V internally unless they touch another PEC region with

a defined potential. In the latter case this defined potential is used

for the internal potential setting. The implicitly set potentials

are not visualized in this view. You can change this default behaviour

of sourceless PEC regions in the Specials

dialog box of the electrostatic solver (Simulation:

Solver ![]() Start Simulation

Start Simulation ![]() ) from Grounded

to Floating meaning that all

PEC regions to which no source is assigned will be considered like floating

potentials.

) from Grounded

to Floating meaning that all

PEC regions to which no source is assigned will be considered like floating

potentials.

The default setting for the background material has to

be adapted to the problem. Open the Background

Properties dialog box (Simulation:

Settings ![]() Background

Background ![]() ). The Material type

has been set to Normal already

by the project template. Furthermore, a surrounding space of 1cm to the

structure is needed. If not already set, please check the Apply

in all directions check-box and enter a value of 1 in the Distance field. These settings will

lead to a simulation with 1 cm additional vacuum space in each direction.

). The Material type

has been set to Normal already

by the project template. Furthermore, a surrounding space of 1cm to the

structure is needed. If not already set, please check the Apply

in all directions check-box and enter a value of 1 in the Distance field. These settings will

lead to a simulation with 1 cm additional vacuum space in each direction.

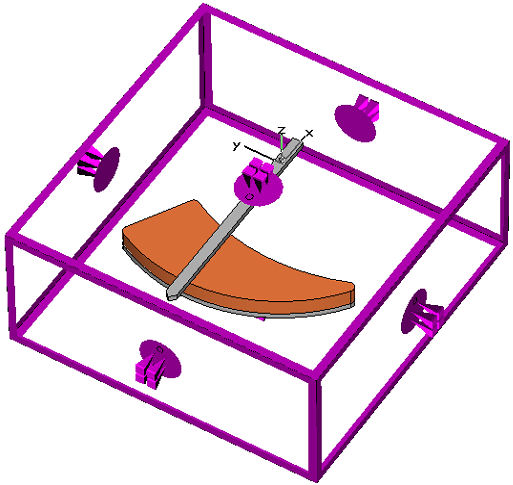

Next, the boundary settings are specified. To this end,

open the Boundary Conditions

dialog box via Simulation: Settings ![]() Boundaries

Boundaries ![]() . For the modeled problem, no symmetry conditions can

be used and the device has to be modeled in free space. Thus, all boundary

conditions should be changed from type electric to type open. As long

as the Boundaries tab is open in the Boundary Conditions dialog box, the

currently set boundary conditions are displayed together with the model

in the Modeler View:

. For the modeled problem, no symmetry conditions can

be used and the device has to be modeled in free space. Thus, all boundary

conditions should be changed from type electric to type open. As long

as the Boundaries tab is open in the Boundary Conditions dialog box, the

currently set boundary conditions are displayed together with the model

in the Modeler View:

Model with open boundary conditions

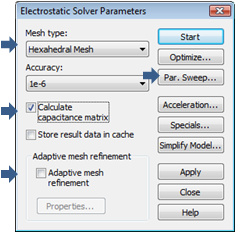

The calculation of the electrostatic fields should be

performed for several pointer angles. Therefore, a parameter sweep

for the previously defined parameter angle will be performed. The

first step is to set the solver parameters. Therefore, launch the

Electrostatic Solver Parameters

dialog box by pressing Simulation:

Solver ![]() Start Simulation

Start Simulation ![]() . With the Mesh

type setting you may choose between a hexahedral or tetrahedral

mesh to discretize the calculation domain. The chapter Tetrahedral

Meshing Strategy will focus on this subject. For the moment,

select Hexahedral Mesh. Please

check the Calculate capacitance matrix

button to enable the capacitance matrix calculation, and disable the Adaptive mesh refinement.

. With the Mesh

type setting you may choose between a hexahedral or tetrahedral

mesh to discretize the calculation domain. The chapter Tetrahedral

Meshing Strategy will focus on this subject. For the moment,

select Hexahedral Mesh. Please

check the Calculate capacitance matrix

button to enable the capacitance matrix calculation, and disable the Adaptive mesh refinement.

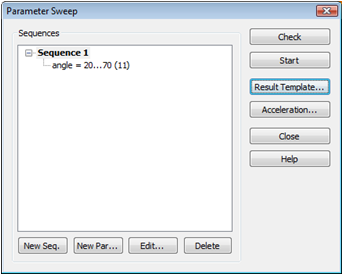

Continue with setting up the parameter sweep by pressing the Par. Sweep... button. The Parameter Sweep dialog box opens and the Electrostatic Solver Parameters dialog box is closed. First, you should add a sweeping sequence by clicking on the New seq. button. Then Sequence 1 appears in the Sequences frame. Next the sweeping parameter has to be added to the newly defined sequence. Clicking on the New Par... button leads you to the Parameter Sweep Parameter dialog box.

Please choose the parameter angle from the Name drop list and check the Sweep checkbox in this dialog window. Now you can enter the range that is used for the variation of the parameter by typing 20 in the From field and 70 in the To field. In addition, enter 11 in the Steps field. These settings indicate that the pointer angle is varied from 20° up to 70° in steps of 5° when the parameter sweep is running.

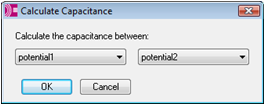

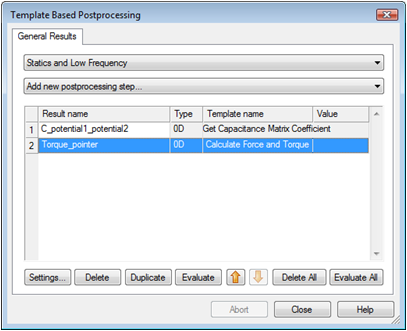

Finally, add the results of interest which should be recorded by the parameter sweep from the individual calculations; this will allow a comparison of the different calculations with regard to the parameter value. To this end, click the Result Template... button. In the Template Base Postprocessing dialog box, which will pop up automatically, select the template group Statics and Low Frequency and the postprocessing step Get Capacitance Matrix Coefficient. Now you can define different combinations of the defined potentials, each representing one coefficient in the capacitance matrix. In this example, we focus on the capacitance between potential1 and potential2. Confirm this setting with OK.

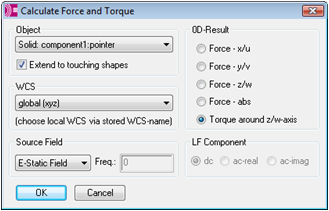

A second watch is used in this tutorial to analyze the torque on the pointer for a moment axis in the positive z-direction from the coordinate axis origin. Therefore, select Calculate Force and Torque from the Add new postprocessing step... drop down list to open the dialog box for the force and torque calculation. Select the pointer solid from the Object drop down list (component1:pointer) and Torque around z/w-axis in the 0D-Result frame. The default axis (0,0,1) and origin (0,0,0) will be used for the torque computation. Finally, select the E-Static Field in the Source Field frame. Due to the distance between the pointer and the scale, the pointer is completely surrounded by background material so that the state of the checkbox Extend to touching shapes has no influence on the result in this case. Confirm these settings with OK.

The Template Based Postprocessing dialog box should now contain two entries:

Leave this dialog box with the Close button. Back in the Parameter Sweep dialog box, press the Start button of the Parameter Sweep dialog box. The results are generated in several solver runs with the structure modified by the parameter variation. After the simulation process is finished you can leave the Parameter Sweep by pressing the Close button.

Please note that the results might differ slightly depending on the operating system and the architecture of the machine with which they were computed.

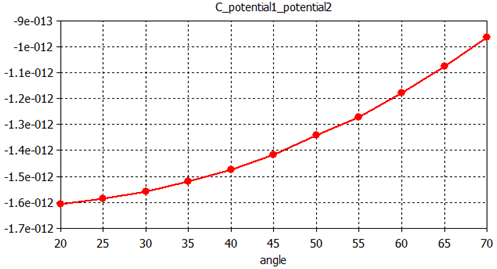

One of the main results is the capacitance between pointer

and ground. This result is automatically generated by the capacitance

watch and can be accessed under the Tables

folder in the navigation tree. There you can select Tables

![]() 0D Results

0D Results ![]() C_potential1_potential2 to view

the capacitance plotted vs. the pointer angle. It can be seen that

the geometry results in a quadratic variation in the capacitance as a

function of angle.

C_potential1_potential2 to view

the capacitance plotted vs. the pointer angle. It can be seen that

the geometry results in a quadratic variation in the capacitance as a

function of angle.

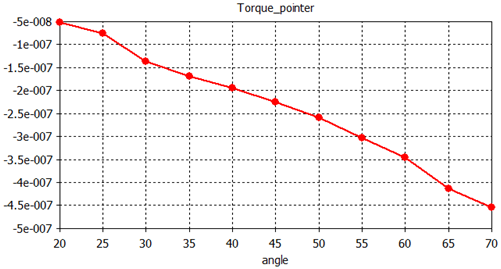

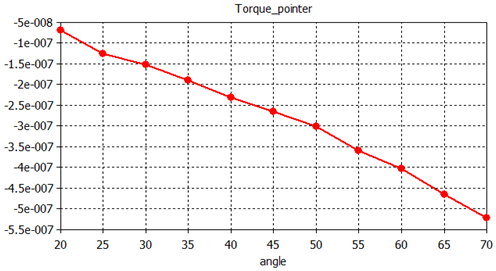

The strong relationship between capacitance and torque

leads to a linear torque with respect to the angle. This allows the

use of this device as a measuring instrument. Select Tables

![]() 0D Results

0D Results ![]() Torque_pointer in the Navigation Tree to view the torque

plotted vs. the pointer angle.

Torque_pointer in the Navigation Tree to view the torque

plotted vs. the pointer angle.

A static field calculation is mainly affected by two sources of numerical inaccuracies:

Numerical errors introduced by the iterative linear equation system solver.

Inaccuracies arising from the finite mesh resolution.

In the this section we provide hints on how to minimize these errors and achieve highly accurate results.

CST EM STUDIO uses an iterative linear equation system solver to solve the discretized field problem. This means that the iterative solver will stop a calculation when a given accuracy is reached. Generally, the default accuracy setting of 1e-6 is sufficient for most calculations. In some cases, however, the solver will give you a warning that results are inaccurate and that you should consider increasing the solver accuracy.

Inaccuracies arising from the finite mesh resolution are usually more difficult to estimate. The only way to ensure the accuracy of the solution is to increase the mesh resolution and recalculate the results. When they do not change significantly anymore as the mesh density is increased, then convergence has been achieved.

In the above example, you have used a modified default

mesh. The easiest way to test the accuracy of the results is to use

the fully automatic mesh adaption that can be switched on by checking

the Adaptive mesh refinement

option in the Electrostatic Solver Parameters

dialog box (Simulation:

Solver ![]() Start Simulation

Start Simulation ![]() ). When you activate the adaptive mesh refinement

and restart the solver, several solver passes will be performed. Finally,

you can visualize the maximum difference of the energy error for two subsequent

passes by selecting 1D Results

). When you activate the adaptive mesh refinement

and restart the solver, several solver passes will be performed. Finally,

you can visualize the maximum difference of the energy error for two subsequent

passes by selecting 1D Results ![]() Adaptive Meshing

Adaptive Meshing ![]() Error from the navigation tree.

Error from the navigation tree.

In this example, the energy deviation between the first and the second pass is about 4%, which indicates that the adaptive mesh refinement was required here to obtain highly accurate results. Generally speaking, global results like energies are less susceptible to discretization errors than local results like field values.

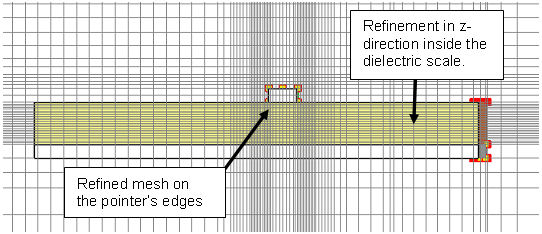

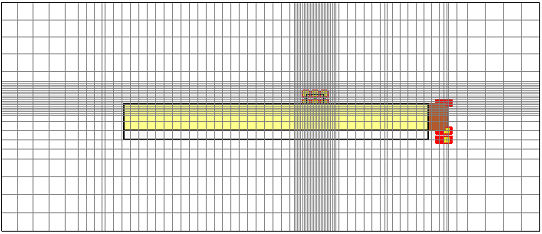

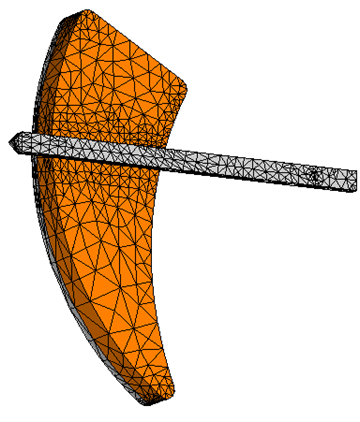

When analyzing the refined mesh (Simulation:

Mesh ![]() Mesh View

Mesh View ![]() ), you should note

that it has been refined particularly around the pointer's edges and in

the z-direction inside the dielectric scale.

), you should note

that it has been refined particularly around the pointer's edges and in

the z-direction inside the dielectric scale.

This knowledge can be used to improve the expert-based mesh manually. A manually refined mesh offers the advantage of saving computation time because the mesh adaptation can be switched off for the next parameter sweep. Because fields change rapidly on the pointer's edges and not inside the pointer's volume, it is advisable to apply an edge refinement to this body. In contrast, the mesh adaptation refined the mesh inside the dielectric scale in the z-direction. Therefore, it is convenient to specify a maximum z-step-width inside the scale solid.

Select the pointer in the navigation tree select Local Mesh Properties from the context menu. In the Local Mesh Properties dialog box for this solid, activate the checkbox Use Edge refinement factor and increase its refinement value to 10:

To refine the mesh inside the scale solid, select it in the navigation tree, choose Local Mesh Properties from the context menu and enter a maximum step-width value of 0.02 in the z-direction (Dz):

The manually refined mesh includes the information extracted from the previous adaptation sequence. It has been sufficiently refined and you may therefore enter the solver dialog box again and switch off the adaptive mesh refinement. When you start the parameter sweep with the improved mesh, you will notice that the capacitance curves have not changed significantly, while the torque curve now meets the expectations much better compared to the first sweep:

Because field singularities appeared on the pointer's PEC edges, the mesh refinement within these regions allowed the solver to produce more accurate results. On the other hand, these fields are used to compute the pointer's torque. So in this case, you have a global result depending strongly on local field values.

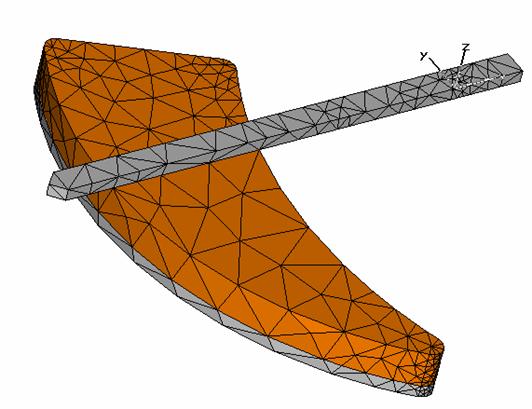

As mentioned above, CST EM STUDIO provides two types of mesh. During the previous chapters you became quite familiar with the hexahedral meshing strategy. To get an impression of the tetrahedral meshing method, we recommend that you read this chapter. A detailed discussion of the different meshing strategies including mesh adaptation can be found as well in the CST EM STUDIO Workflow & Solver Overview manual.

Before you start the tetrahedral simulation, it is advisable

to make a copy of the current project under a different name. Then switch

to "Tetrahedral Mesh" by selecting Simulation:

Mesh ![]() Global Properties

Global Properties ![]() Tetrahedral. In the Tetrahedral

Mesh Properties dialog box please change the Min.

number of steps value to 10

and confirm your settings by clicking the OK

button. When you now enter the Electrostatic

Solver dialog box (Simulation:

Solver

Tetrahedral. In the Tetrahedral

Mesh Properties dialog box please change the Min.

number of steps value to 10

and confirm your settings by clicking the OK

button. When you now enter the Electrostatic

Solver dialog box (Simulation:

Solver ![]() Start Simulation

Start Simulation ![]() ), the Tetrahedral

Mesh should be the active Mesh

Type. Start the simulation. A couple of seconds later, the calculations

will be finished and you can examine the tetrahedral mesh and the appropriate

results. To get an impression of the tetrahedral mesh, select Simulation:

Mesh

), the Tetrahedral

Mesh should be the active Mesh

Type. Start the simulation. A couple of seconds later, the calculations

will be finished and you can examine the tetrahedral mesh and the appropriate

results. To get an impression of the tetrahedral mesh, select Simulation:

Mesh ![]() Mesh View

Mesh View ![]() :

:

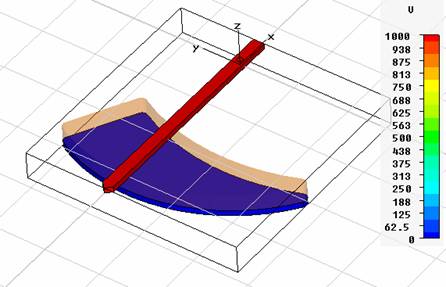

Although this mesh is relatively coarse, it delivers

a good impression about the fields. Select the Potential

entry from the 2D/3D Results

folder in the navigation tree and take a look at the electric field (2D/3D Results ![]() E-Field) :

E-Field) :

|

|

|

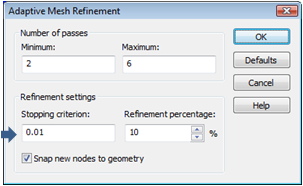

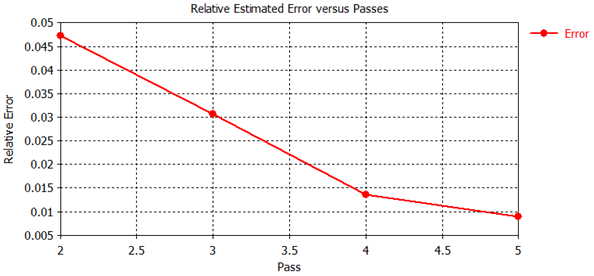

An adaptive mesh refinement is also available for the

tetrahedral meshing method. Reenter the solver dialog box (Simulation:

Solver ![]() Start Simulation

Start Simulation ![]() ) and activate the Adaptive

mesh refinement. Before you restart the solver, enter the adaptive

mesh properties dialog by pressing the Properties

button:

) and activate the Adaptive

mesh refinement. Before you restart the solver, enter the adaptive

mesh properties dialog by pressing the Properties

button:

Since the hexahedral adaptation run was able to deliver

a relative error of less than 1%, you may also this time set the convergence

criterion to a value of 0.01. Leave the dialog by pressing the OK

button and start the tetrahedral adaptation run by pressing Start. A

few moments later you can observe the refined mesh by activating the mesh

view (Simulation:

Mesh ![]() Mesh View

Mesh View

![]() ):

):

The mesh has been refined roughly at the same locations

where the hexahedral method added new mesh lines, specifically, the surroundings

of the pointer. Finally, examine the adaptation convergence curve

by selecting 1D Results ![]() Adaptive Meshing

Adaptive Meshing ![]() Error from the navigation tree:

Error from the navigation tree:

The relative error between two subsequent passes dropped below 1% within 4 calculation passes. Please note that the final results as well as the number of calculation passes can differ slightly depending on the operating system and the architecture of the machine which is used for the simulation.

Congratulations! You have just completed the electrometer tutorial that should have provided you with a good working knowledge on how to use the electrostatic solver. The following topics have been covered:

General modeling considerations, using templates, etc.

Modeling curves using the circle creation tool in combination with trim curves tool.

Creating shapes from planar curves using the extrusion tool.

Model shapes using the cylinder- and brick creation tool.

Applying blend and chamfer operations on existing shapes.

Define potentials on PEC solids.

Define boundary conditions.

Setup the electrostatic solver.

Setup of parameter sweep watches.

Perform a parameter sweep.

Visualize the results of the parameter sweep.

Obtain accurate and converged results using the automatic mesh adaptation.

Get a first impression of the tetrahedral meshing method.

You can obtain more information for each particular step from the online help system that can be activated either by pressing the Help button in each dialog box or by pressing the F1 key at any time to obtain context sensitive information.

In some instances, we have referred to the CST EM STUDIO Workflow & Solver Overview manual that is also a good source of information for general topics.

In addition to this tutorial you can find more electrostatic calculation examples in the Examples folder in your installation directory. Each of these examples contains a Readme item in the navigation tree that will give you more information about the particular device.

And last but not least: Please also visit one of the training classes, held regularly at a location near you. Thank you for using CST EM STUDIO.