|

|

|

|

hexahedron |

tetrahedron |

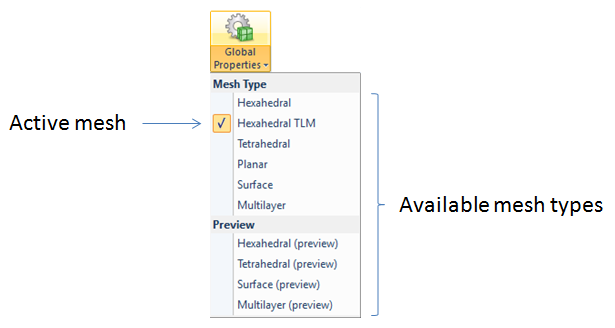

Setting the mesh type

You select the mesh type for your computation in the respective solver dialog. Please note that almost all CST solvers work with a hexahedral mesh, while only some solvers provide a tetrahedral mesh method.

Another way to select the mesh type is by using

the menu available with Home:

Mesh Global Properties

Global Properties ![]() . However, this is just for previewing

the mesh. A change of the solver method will change the active mesh type.

. However, this is just for previewing

the mesh. A change of the solver method will change the active mesh type.

Differences between CST hexahedral and tetrahedral meshes.

CST hexahedral meshes:

In general, hexahedral meshes do not conform to material jumps; please note that this is not necessary because CST provides the Perfect Boundary Approximation® (PBA) in combination with hexahedral meshes.

Hexahedral meshing is very robust even for most complex imported geometries.

Hexahedral meshes are highly structured and lead to very fast computations.

In contrast, CST tetrahedralmeshes

are conform to solid-boundaries and consequently conform to material jumps.

The mesh refinement can be local with respect to all coordinate directions, i.e. single elements can be refined.

Which mesh type is most appropriate for a given simulation task?

It is difficult to provide a general statement on how to decide which mesh type should be applied for a given problem. However, as a rule of thumb, using CST hexahedral meshes will often lead to faster computations because the solver can take advantage of their additional structure. Moreover, hexahedral meshing is very robust concerning complex geometries. This may be important if you must deal with imported structures.

However, if your problem setting includes strongly local details in the geometry or solution, structured hexahedral meshes may produce a large overhead in the number of elements for the part of the computational domain that does not need a fine mesh. For these types of problems, tetrahedral meshes are more suitable because they offer more flexibility.

|

|

A typical example of when the application of a tetrahedral mesh may be recommended is the presence of small, curved gaps or thin, curved dielectric solids. In these cases, a sufficiently fine structured hexahedral mesh may include many mesh cells, whereas a tetrahedral mesh can resolve the gap or thin-curved solid locally (see the pictures below). Hence, using a tetrahedral mesh may lead to a smaller number of unknowns for such situations. One must decide between flexibility or higher speed for more unknowns. Clearly, some experience is necessary to know which mesh type fits best for a given problem. Below are given the different mesh types for the geometry on the left. |

|

Using hexahedral meshing for this example , the mesh refinement is not restricted to the fine geometry. |

|

Tetrahedral meshing is more flexible, small mesh cells appear only in the surrounding of the small scale geometry and are conform to the model geometry. |

Verification by comparison

You can get crucial benefit by the use of all, a tetrahedral and a hexahedral mesh for the same problem: The results can be compared. This yields an additional validity check for your numerical results.

Note that this is not a time-consuming task. In contrast to the use of different software tools for validation you can use different solver methods in the same CST software without setting up your computational model again!

See also

Mesh Generation Overview (Hexahedral), Mesh Generation Overview (Tetrahedral),Mesh View (Hexahedral), Mesh View (Tetrahedral)